Why Add An ABB Inverter To Crushers

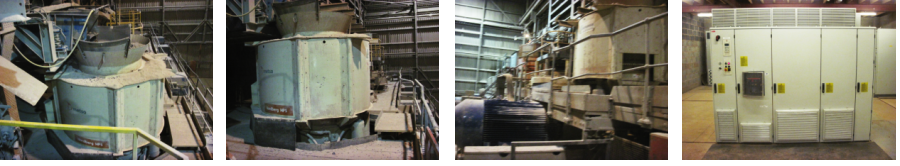

A crusher is used to take large minerals and make them smaller. These can often be large, heavy machines. They are found at quarries and mines to produce the correct sized product for further processing or selling on to the customer. They come in various forms but are usually jaw, cone or impact (hammer) crushers.

Why Add An ABB Inverter To Crushers

Inverters lend themselves to crusher control for the following reasons:

- High starting torque may be required with a limited current draw allowing smoother gentle starts with reduced mechanical and electrical stress.

- Varying the ‘cut point’ of the product on impact crushers – the faster the crusher’s speed the smaller the resultant particles.

- Energy saving by being able to stop the crusher between production runs without the limit of ‘starts per hour’ of other starting methods.

Crushers can be hundreds of kW in power and ABB ‘DTC’ inverters – the new ACS880 range – are the ideal partner for these machines.

The ACS880 range has direct torque control as standard, an all compatible drive the ABB ACS880 range are entirely suitable for crusher applications.

To discuss further the benefits of adding an ABB Inverter to Crushers in your quarry or mine call our sales team on 0115 944 1036 or email [email protected]