Variable speed drives – Are you missing a trick?

Don’t make the mistake of dismissing VSDs as nothing more than motor controllers, says ABB’s Carl Turbitt. To use a drive merely to start and stop a motor and alter its speed is to miss the huge cost saving potential built within the product.

Panels containing control gear for air handling units, fans and pumps are used extensively throughout modern buildings. Within these panels are VSDs and a host of additional components including thermostats used for controlling cabinet fans to save standby losses, timer relays, contactors and doormounted HMIs. The panel might also include a mini PLC for decision making or for controlling the system to behave at different times of the day.

Yet all these components, and more, are not needed as they are already built within the VSD. You don’t need the thermostat as the drive will tell you when its own fans are running, thereby switching on additional cabinet cooling fans automatically, if installed. Timer relays are not required as the drive has a real-time clock, from which timers can be set to either start or stop an application running, depending on operating conditions.

Variable speed drives – Are you missing a trick?

Energy monitoring via a clamp-on meter is no longer necessary as the VSD’s inbuilt energy counter displays in real time how much energy the drive is saving compared to direct-on-line operation, in kWh, MWh, CO2 emissions and even money saved.

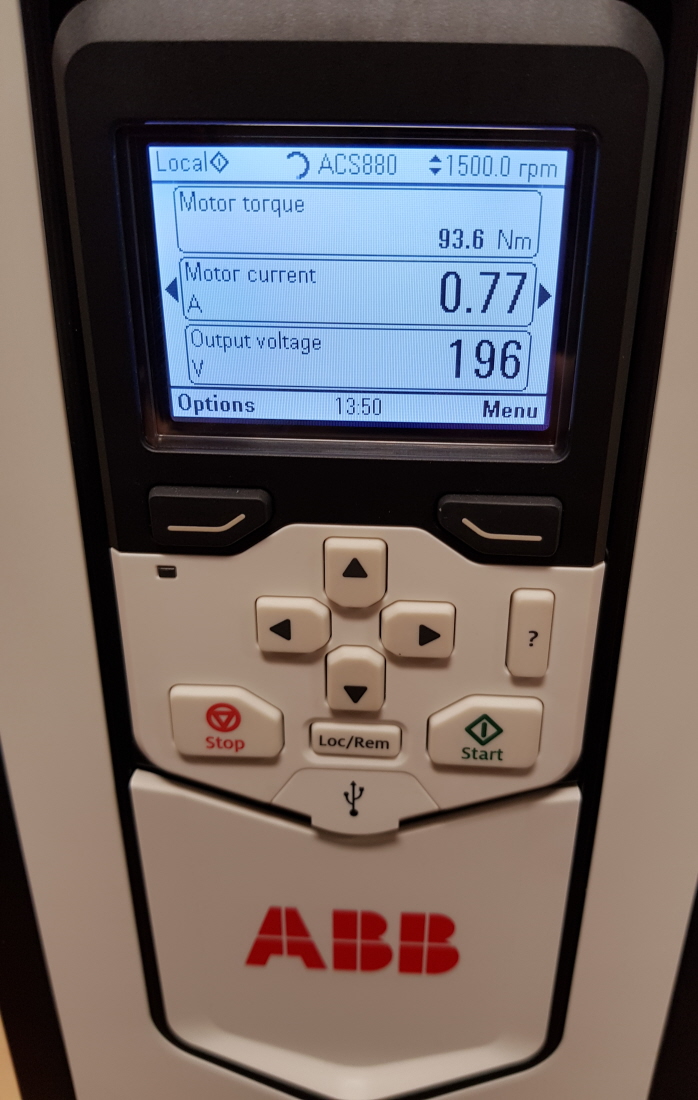

The VSD also removes the need for external HMI displays to be cut into the door of cabinets. Today’s VSD keypad offers 21 variables, displayed via graphs, charts and meter readings that speak the language of any application. There is no need for any analogue meters as the keypad has a view that looks like an analogue moving iron meter, scaled and labelled in the correct customer units. The keypad negates the need for cabinet furniture such as start/stop buttons, as these can be programmed into the keypad.

Text editing means that if you are pumping water, for instance, you don’t need to read the motor’s speed in rpm but rather the actual flow rate in litres per second with scaling factors. The VSD can be customised to present the language of the application or industry and change warnings and trips into plain, simple language – “Pump 2 failed in bay 6, top floor”.

This eliminates the need to connect an HMI to Modbus, saving substantial costs. It also simplifies technical support as the language of the customer is one the drives engineer can easily relate too.

Using the drive’s fieldbus means you can utilise un-used drive I/O to gather telemetry onto the fieldbus system, without having to purchase additional remote I/O stations.

Users need to ask what are they doing with the VSD? Why install a host of additional components in the panel when they are already contained in the drive? Why struggle to manage the cabinet cost, when understanding what’s inside the drive could save up to 50 percent of the cost of cabinet components?

ABB (ABBN: SIX Swiss Ex) is a pioneering technology leader in power grids, electrification products, industrial automation and robotics and motion, serving customers in utilities, industry and transport & infrastructure globally. Continuing a history of innovation spanning more than 130 years, ABB today is writing the future of industrial digitalization with two clear value propositions: bringing electricity from any power plant to any plug and automating industries from natural resources to finished products. As title partner in ABB Formula E, the fully electric international FIA motorsport class, ABB is pushing the boundaries of e-mobility to contribute to a sustainable future. ABB operates in more than 100 countries with about 147,000 employees. www.abb.com