UK Energy and Carbon Reduction Schemes

Making sense of the UK’s energy and carbon reduction opportunities

The UK operates several different energy and carbon reduction schemes that aim to incentivise reductions in industrial and commercial energy consumption. Some schemes are similar in scope, while others apply only to certain organisations. All of them, when leveraged effectively, can reduce your energy bills and carbon footprint by embracing energy efficient technologies.

Climate Change Levy (CCL)

What is it?

An energy reporting scheme which levies a tax on energy delivered to non-domestic users in the UK

Who does it apply to?

All commercial and industrial energy users. Certain types of organisation can claim exemptions, for instance charities engaged in non-commercial activities, or businesses that

use extremely low amounts of energy i.e., less than 1,000 kWh per month. Previously the scheme provided exemptions on energy generated from renewable sources, but this is no

longer the case.

What are the requirements?

The tax is collected and passed to HMRC by your energy supplier, and so the requirements of the CCL are automatically met simply by paying your energy bills. Reduced rates can be obtained by entering into a Climate Change Agreement (CCA).

Anything else I should know? The most effective way of reducing your CCL rate is simply to use less energy, which is best achieved by investing in energy saving equipment such as high efficiency electric motors and variable speed drives (VSDs).

Climate Change Agreement (CCA)

What is it?

A voluntary agreement made between a business and the Environment Agency whereby the business commits to reducing its energy use and CO2 emissions, and enhanced

reporting of its energy use against 2-year target periods. Adhering to the agreement entitles the business to a discounted rate of Climate Change Levy (CCL).

Who does it apply to?

Any business that pays the CCL. There are two types of CCA – umbrella agreements and underlying agreements. Umbrella agreements are handled by sector associations (check the

government’s CCA sector contact list), while underlying agreements can be held by an operator of an individual facility, or a group of facilities within a particular sector.

What are the requirements?

The particular requirements of a CCA will differ from sector to sector. Companies wishing to enter into a CCA must apply first to its sector association. Once a CCA is in place, the

company must then abide by the terms of the agreement, which will commit the company to reducing its energy use and CO2 emissions, and reporting against the efficiency targets

set out in the agreement.

Anything else I should know?

The CCA scheme has recently been extended until March 2025.

Energy Saving Opportunity Scheme (ESOS)

What is it?

An energy assessment and reporting scheme for large businesses. It aims to identify energy saving opportunities, and encourage organisations to implement more energy efficient equipment and technologies.

Who does it apply to?

Any organisation that fulfils one or more of the following

criteria:

• 250+ employees

• Turnover greater than £45 million

• Balance sheet shows more than £38.5 million

Public sector organisations are exempt from ESOS

requirements.

What are the requirements?

Organisations that qualify must carry out an ESOS assessment every four years. Deadlines are set by the Environment Agency, and are the same for every organisation. The deadline for ESOS phase 3 compliance is December 5, 2023, and December 5, 2027 for phase 4. The assessment takes the form of an audit of the energy used by an organisation’s buildings, industrial processes and transport. The assessment should measure total energy use, identify areas of significant energy consumption, and recommend actions that will help to reduce usage. The assessment can be either be carried out in house, or by approved ESOS assessors. Whilst compliance is mandatory, it is not mandatory to act upon the recommendations in the report. Failure to achieve compliance can result in fines.

Anything else I should know?

Companies that choose not to act upon recommendations in the report, are potentially missing out on substantial benefits in energy and cost savings. The government estimates that investing, for example, just £15,000 in energy efficiency measures based on ESOS report recommendations can lead to an average reduction in bills of up to £56,400

Streamlined Energy & Carbon Reporting (SECR)

What is it?

An annual UK energy and carbon assessment and reporting scheme, designed to increase awareness of energy consumption and costs within organisations, and encourage

decarbonisation through the adoption of energy efficient technologies.

Who does it apply to?

SECR is mandatory for any UK organisation meeting at least two of the following three criteria:

• 250+ employees

• Turnover or gross income greater than £36 million

• Balance sheet assets showing £18 million or more

Public sector organisations are exempt from SECR requirements. Companies with extremely low energy usage are also exempt, but must provide a statement to that effect in their Annual Report.

What are the requirements?

Qualifying organisations must carry out and submit an audit of energy usage and carbon emissions every year, and make the information public in their Annual Report. The methodology used must be disclosed, and although no methodology is prescribed, it must be robust, transparent and widely accepted. No allowances or levies need to be paid, but failure to report properly can lead to fines.

Anything else I should know?

SECR and ESOS share many similarities, but where ESOS focuses on looking forward for potential energy saving opportunities to be implemented in the future, SECR looks back at the previous financial year, reporting on what actions have actually been taken to improve energy efficiency.

Discontinued schemes

Carbon Reduction Commitment (CRC) – discontinued in 2019

Enhanced Capital Allowances (ECA) – discontinued in 2020.

Building Regulations – Part L

Part L is a building regulation that sets standards for energy performance and carbon emissions of both new and existing

buildings.

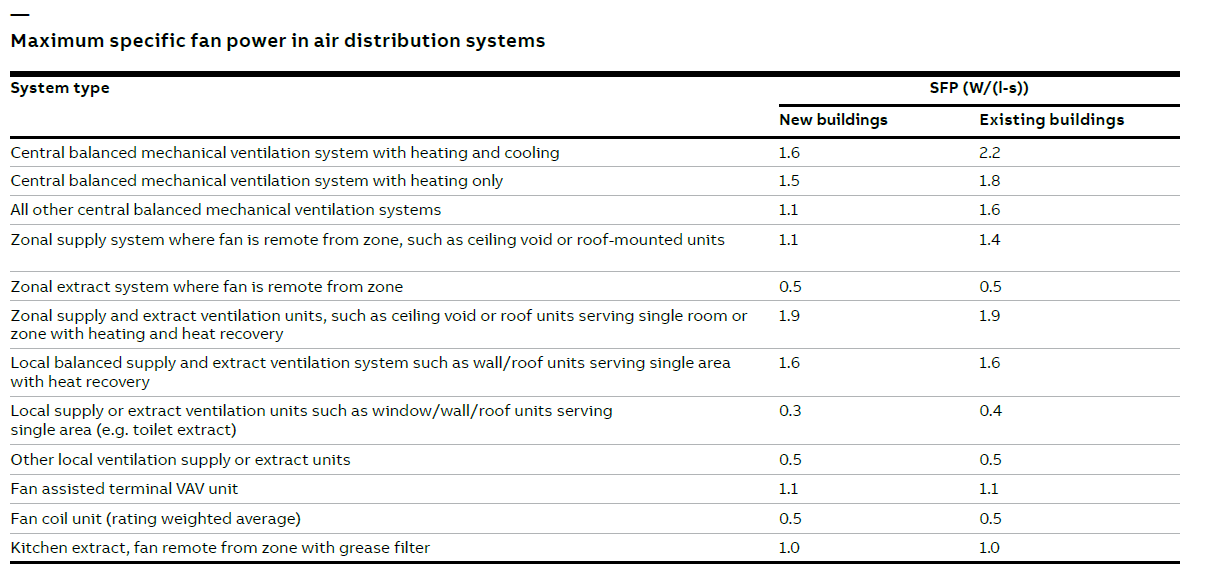

• Air distribution is covered under Section 10 of the Building Regulations – Part L

• Air handling systems should be capable of achieving a specific fan power at 25% of design flow rate no greater than that achieved at 100% flow rate. It also requires that all fans above 1100 W should have a means of efficient variable flow control. The government guidance suggests VSDs as a reasonable provision.

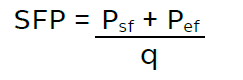

• Specific fan power (SFP) of an air distribution system means the sum of the design circuit-watts of the system fans that supply air and exhaust it back outdoors, including losses through switchgear and inverters (i.e. total circuit-watts for the supply and extract fans), divided by the design air flow rate through that system

where:

SFP is the specific fan power demand of the air distribution system in kW x m3 x s

Psf is the total fan power of all supply air fans at the design air flow rate in kW

Pef is total fan power of all exhaust air fans at the design air flow rate in kW

q is the design air flow rate through the system, which should be the greater of either the supply or exhaust flow

In terms of SFP for the whole building, any fan powered terminals shall be included when they are connected to the main air supply system

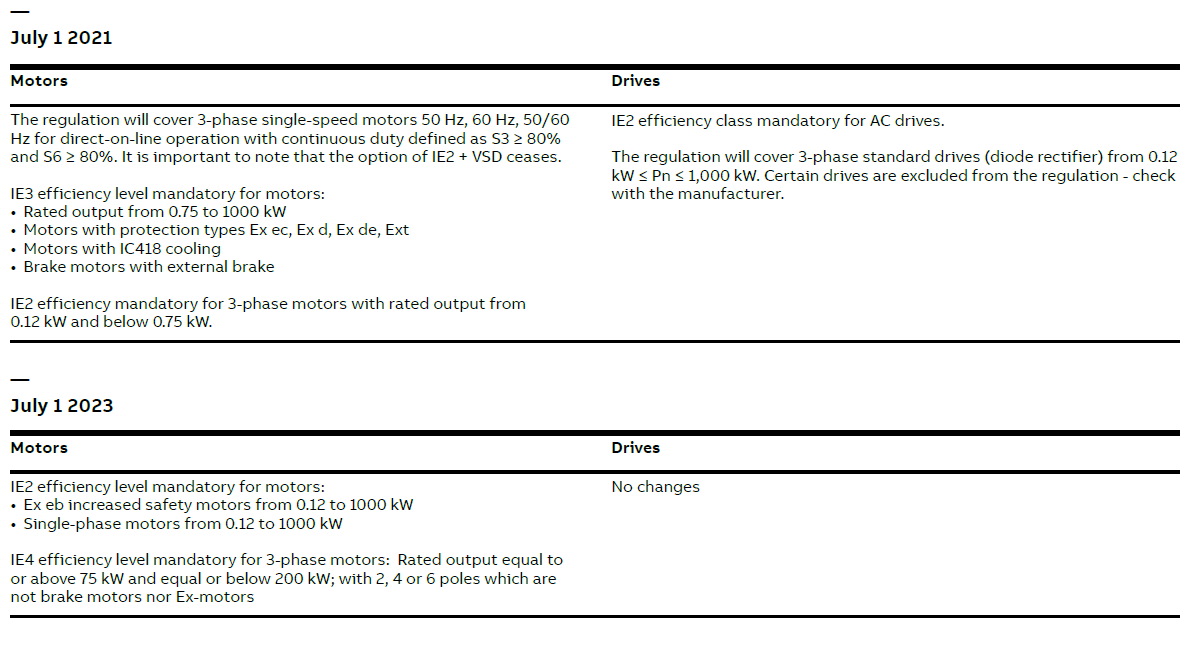

EU Ecodesign Regulation for motors and drives

The Ecodesign Regulation sets mandatory minimum efficiency levels for electric motors and drives introduced into the EU markets. It uses efficiency classes created by the International Electrotechnical Commission (IEC), a global standard-setting organisations. The implementation will be done in two steps: on July 1, 2021 and July 1, 2023.

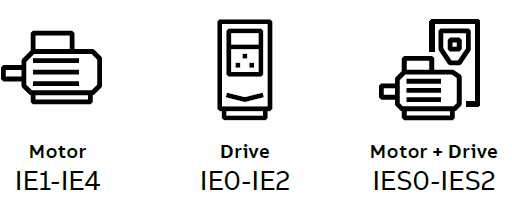

Motor efficiency classes

IEC/EN 60034-30-1 establishes four efficiency classes for electric motors. It applies to single-speed motors that are rated according to IEC 60034-1 or IEC 60079-0 (explosive

atmospheres) and designed for direct-on-line (DOL) operation. The efficiency values are based on frequency, number of poles and motor power, and the efficiency classes

are (low to high) IE1 to IE4.

Drive efficiency classes

IEC 61800-9-2 defines efficiency classes for AC drives, which are also referred to as ‘complete drive modules’ (CDM). The efficiency classes range (low to high) from IE0 to IE2. These classes apply to AC drives rated 100 to 1000 V and 0.12 to 1000 kW.

Motors and drives combined

IEC 61800-9-2 defines efficiency classes for AC drives and motors in combination, which are also called ‘Power Drive Systems’ or PDS. These IES classes range (low to high) from IES0 to IES2. The classes are valid for motors and AC drives rated 100 to 1000 V, and 0.12 to 1000 kW. Note that the Ecodesign Regulation does not set minimum efficiency requirements for PDS.

Proven technologies for energy saving

ABB motors and drives are recognised by a range of industry organisations for their energy saving capabilities.

Synchronous reluctance motors (SynRM)

Synchronous reluctance motors (SynRM) ABB’s SynRM electric motors have been awarded an Efficient Solution Label by the Solar Impulse Foundation. The label is granted to solutions that meet high standards of both sustainability and profitability, and involves a strict assessment by independent experts.

The SynRM motor achieves IE5, the highest efficiency class available, and compared to an IE3 motor can reduce CO2 emissions by 22,000 kg per year for a 315 kW application – equivalent to taking nine petrol cars off the road. SynRM technology combines the performance of a permanent magnet motor with the simplicity and service-friendliness of an induction motor. The rotor has neither magnets nor windings and has virtually no power losses.

Variable speed drives

ABB variable speed drives are included on the Energy Technology List (ETL), a government-approved list of verified energy efficient products, along with a range of electric motors. Products on the list will typically fall within the top 25 percent of energy efficient equipment for aparticular technology category in the UK market.

The ETL encourages businesses to invest in high performance energy efficient equipment by reducing the time and costs incurred through researching and purchasing equipment. It is underpinned by regular independent evaluations across a range of technology categories, providing a dynamic benchmark for what represents premium performance for different types of equipment. The Energy Technology List can be accessed here.

Here to help you unlock your energy saving potential

Electric motors are found everywhere throughout industrial and commercial facilities, from heavy machinery to HVAC plant rooms. Each one of these motors represents an opportunity to substantially cut costs by installing variable speed drives (VSDs) to control a motor’s speed. Even a 20 percent reduction in motor speed can deliver a 50 percent energy saving, while also offering other benefits such as improved reliability through reduced stress on mechanical parts. Payback times are typically two years, but can be as low as six months.

High efficiency motors and VSDs can be used as a key component in energy reporting, while providing substantial savings in reducing energy bills and carbon emissions to ensure enhanced compliance with applicable energy schemes and legislations.