Try the ABB Energy Snapshot

The ABB Energy Snapshot is a free, no obligation service that in half a day identifies the potential energy saving opportunities in your motor-driven applications, and shows you how to turn that potential into reality.

What’s in the ABB Energy Snapshot?

One snapshot – three different perspectives. Purchasing decisions aren’t always just made by one person, which is why with the ABB Energy Snapshot, each stakeholder in the decision-making process receives a bespoke report that speaks the same language they do. It provides key personnel with the information and clarity they need to realise the energy saving potential on motor-driven applications, and dramatically cut costs.

Get full visibility on investments…

• Financial controllers need to have the facts at their fingertips – without getting bogged down in technical jargon.

• Snapshot report incorporates actual plant values to provide credible, impartial analysis of current plant performance and potential savings for motor-driven applications.

• Monetary values are calculated using plant energy running costs measured on-site.

• Day/night and peak/off-peak energy rates and alternative energy supplies taken into account (e.g. rooftop solar panels, heat recovery).

… by unlocking the hidden figures

• Savings are presented within the context of energy schemes such as ESOS, SECR etc.

• The Snapshot’s report uses basic explanations where appropriate for technical concepts; e.g. energy savings can be expressed as an equivalent number of lightbulbs, or CO2 expressed in air miles.

• Raw data is displayed along with charts and graphics to clearly demonstrate current and projected running costs, investment, savings forecasts, payback points and energy/CO2 saved.

• Snapshot report can be used to build a compelling business case for investment in energy saving equipment.

Identify the big energy consumers…

• Pressure is on industry to reduce energy costs and carbon footprint wherever possible.

• Energy Snapshot report identifies up to five of the biggest energy consumers across your plant, and provides a realistic and achievable action plan to rapidly reduce consumption and costs.

• Comprehensive analysis of motor energy usage can subsequently be used as part of SECR and ESOS reporting schemes.

• On-site assessment takes into account specific environmental considerations unique to your facility and operations.

… then unlock the saving potential

• Variable speed drives often represent a small investment with big reward for many motor-driven applications.

• Snapshot report provides specific equipment recommendations with detailed product descriptions and cost/benefit analysis.

• Engineer’s notes describe drive and motor technical considerations within the context of your applications, along with explanations in engineering and layman’s terms for predicted savings.

• Fitting a drive to a motor with no speed control can reduce energy usage by up to 60 percent.

• IE4 and higher efficiency class motors are among the most efficient available, contributing to further energy reduction.

Lower operational overheads and production risks…

• Operational costs must be controlled without compromising safety of plant, personnel or end product.

• Plant shutdowns are costly, from lost production time, spoiled goods and reputational damage.

• Snapshot report provides detailed analysis of your existing plant equipment, giving you insight into motor condition.

• Based on available data, recommendations are provided as to whether upgrading equipment could reduce operating costs.

• Engineer’s notes provide maintenance personnel with the technical information to explain and justify recommendations.

… through advanced motor and drive technologies

• Soft starting avoids sudden shock loading, and can be used to reduce motor speed leading to less wear and tear to gears, belts and driven machine, reducing likelihood of breakdowns.

• Report takes into account application types and actual motor condition, e.g. size, load, age, number of rewinds, as well as plant environmental considerations, to give you a true snapshot of your installed base.

• Free CPD-approved training is available from ABB to help industry professionals continue to extract optimal equipment performance with minimal downtime.

• Report provides specific equipment recommendations with detailed technical notes including existing unused or underused drive functions, and installation considerations relevant to your applications.

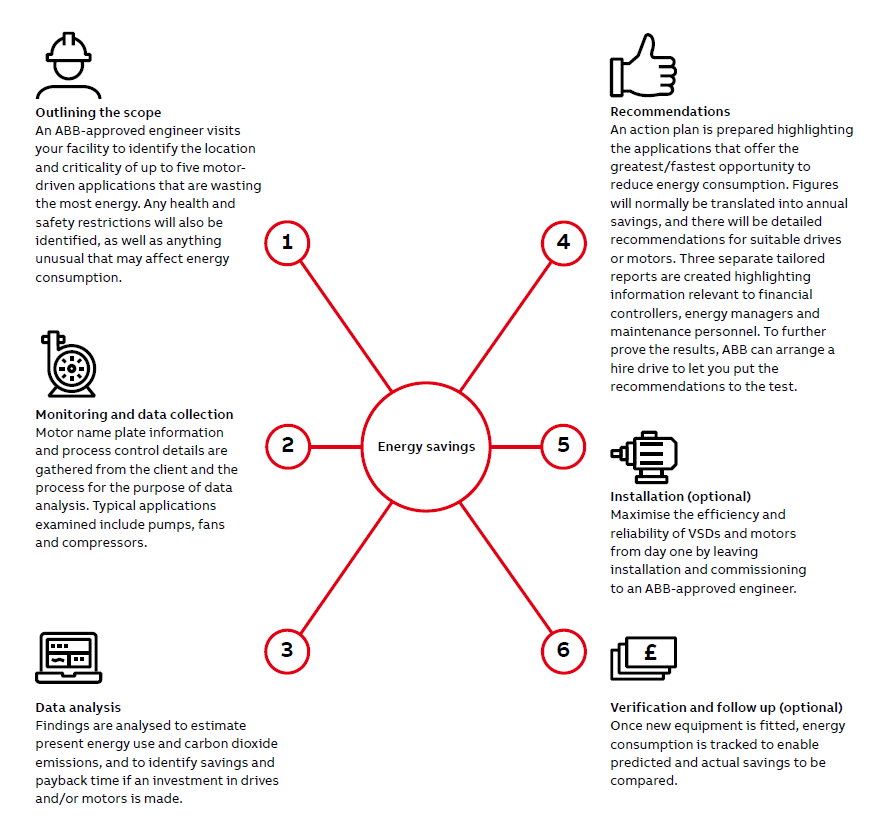

How it works

6 steps towards cutting your energy bills by up to 60%

Book an Energy Snapshop

At IDS we are an ABB VP you can book an Energy Snapshot by clicking here call us on 0115 944 1036 or email [email protected]