Seven virtues of variable speed drives to consider in 2020

ABB’s Carl Turbitt looks at seven very diverse opportunities offered by variable speed drives that he believes can significantly improve building services efficiency in 2020.

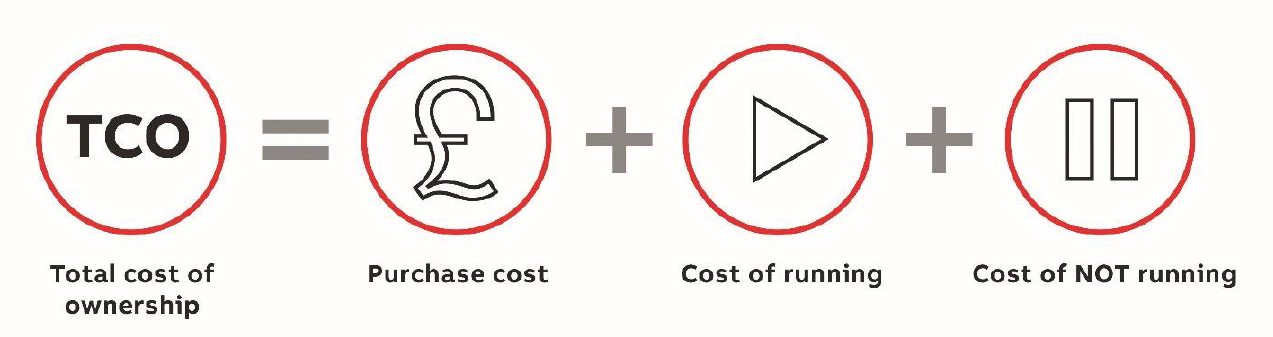

Total cost of ownership

As engineers, one of the most important challenges we face is the need to ensure that building services – whether they be an entire HVAC process or an individual pump or fan – are running at their most efficient. Clues that things may not be running smoothly could be an excessively high energy bill, or the fact that the maintenance team are forever being called to check various aspects of the system.

With VSDs, there are two very different cost considerations: the cost of running and the cost of NOT running, let’s say, a fan system. These two aspects, together with the purchase price, make up the “cost of ownership” of the entire fan system.

The cost of running comprises the associated energy costs as well as the costs of operating and maintaining the fan and motor. Maintenance costs can also cover major overhauls undertaken to extend the useful life of the system. The cost of NOT running is a direct cost to a process such as the impact that a forced outage can have on a company’s brand and image.

These two costs can be so huge that they dwarf the initial purchase cost. A way to control these costs is to undertake an energy assessment. The assessment quantifies the value provided by investing in premium, leading-edge technology and the inherent reliability this brings. Selecting components with known reliability from a trusted supplier is a good insurance against the cost of NOT running becoming unmanageable.

Engineering optimisation

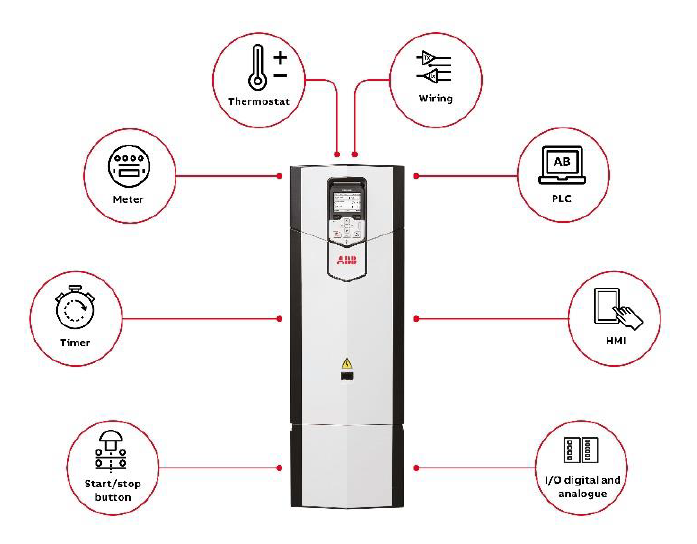

Many HVAC applications, such as air handling units (AHUs), can benefit from the integrated control functions built within a VSD. These functions remove the need for costly external components, thereby saving costs, space and reducing installation time. Many of an AHU’s control functions such as timers and lamps, can be performed by the VSD. Optimising the engineering of the AHUs can remove the need for warning lamps, for example, used to signal dirty or blocked filters or air duct blockages. This is achieved by transferring the wiring directly into the VSD’s I/O, ensuring that any warnings are now shown directly on the keypad.

Furthermore, traditional timers can be replaced by utilising the VSD’s internal real-time clock. The clock can be used to switch the unit on and off according to a pre-programmed schedule. It is also possible to rewire frost thermostats into the VSD. If the external temperature falls below a predetermined level, the VSD’s PID function sends signals to slow down the fan motor which closes the damper and opens the heating valve. The VSD will only speed up the motor once a safe temperature is reached, thereby protecting the motor from potential frost damage.

Ease of use, speed of installation

Time is money and a growing priority in building services is for HVAC components that are easy to install and quick to set up. Today’s VSDs don’t disappoint, and despite their small size, they have complete functionality built-in for controlling not only fans, pumps and compressors, but also more complex HVAC equipment like air-handling units.

While the built-in features significantly reduce installation time, a VSD’s intuitive control panel with a HVAC-specific primary settings menu and help assistants makes start-up, commissioning and operation easy. There are ready-made HVAC assistants for pumps, fans, or compressors meaning easier and shorter commissioning times. A Bluetooth® capability enables the commissioning and monitoring of VSDs installed in hard-to-reach areas plus increases personnel safety by keeping users out of arc flash zones.

Other features that simplify installation include quick access to terminals for drive cabling and wiring, side-by-side mounting and small clearance for cooling, saving space in the cabinet. Furthermore, integrated PID controllers, relays, real-time clock, timers and supervision functions eliminate the need for external PLCs, DDCs or BMS.

Adaptive programming

A VSD features adaptive programming software which customises the drive for specific needs without any previous programming knowledge. The “learn it once, use it everywhere” philosophy increases the intelligence of an AHU by replacing basic information such as “filter blocked” or “filters dirty” with proactive prompts such as “check bag filter” or “check panel filter”. The warning is now in terminology suitable for the specific application providing practical guidance on how to remedy. This makes it easier for operators not familiar with the fresh air supply units to react safely.

Electronically commutated motors (ECM)

ECMs are combined with a brushless controller onto the fan assembly. However, if one component fails, the entire unit – including fan, motor and controller – must be replaced. ECM fans have a poor harmonic signature, typically do not come with building management system (BMS) fieldbus protocols and cannot catch spinning loads which for some applications like data centres are a requirement. ECMs are only available in low powers, so several units must be combined into a fan array to reach the desired power. However, this adds components into the system, thereby increasing the probability of failure. If a unit fails, increasing the speed to maintain the flow will take more power, thus not maintaining specific fan power requirements. Adding all the individual units will lead to a higher overall weight of the fan array.

A far more flexible option is to consider some of the other motor technologies such as synchronous reluctance motors (SynRM), permanent magnet (PM) motors or the long-established and traditional induction motor (IM).

Harmonics

Harmonics can cause interference in communication equipment and false readings on measurement devices. Harmonics can trip circuit breakers, blow fuses and cause capacitor failures.

Equipment must be designed to tolerate harmonics in the network and oversizing leads to higher investment costs and under-utilised capacity. The problems caused by harmonics result in increased losses because more energy is wasted due to overheating. Additionally, equipment has a shorter lifetime and is subject to unreliable operation.

Instead of tackling harmonics by adding cooling or over-dimensioning equipment, a better way is to use products that do not cause harmonics in the first place. For instance, a new breed of ultra-low harmonic drive is emerging. These new VSDs produce exceptionally low harmonic content, typically just three percent, exceeding the requirements set by international standards. This compares favourably with the alternative method of using a passive filter, which typically reduces harmonic distortion to between five to 10 percent.

Ultra-low harmonic drives achieve a unity power factor. This high-power factor indicates that the electrical energy is used to its full potential. The VSD reduces the need for additional power factor correction equipment, including filters and large capacitor banks. This new ultra-low harmonic drive can also help to avoid penalty charges set by electrical utilities for poor power factors.

Intelligent pump control

There is a growing use of intelligent VSDs for pump control that represents a major departure from the standard operating practice of using control valves to vary fluid flow. With embedded intelligence, VSDs can provide pump control, pump condition monitoring, protection and traditional energy saving benefits.

“Pump priority” schedules pump operation to enable maintenance planning. It is intended for systems where the consumption rate varies with demand. For example, the drive can be programmed to operate higher capacity pumps during the daytime and smaller units at night. This allows for better maintenance planning and can boost energy efficiency by operating pumps closer to their best efficiency point.

Using VSDs to control pressure and flow improves flow management, minimises maintenance and reduces electrical energy requirements. With smooth VSD control there are no pressure shocks causing noise, erosion or leakage in the pipeline. Intelligent VSDs also increase uptime: parallel drives enable the system to run with 100 percent redundancy. If a defect occurs in one of the pumps, motors or drives, the others will continue operation without any interruption. Further, the running time of the pumps can be controlled with the pump priority function to ensure that wear and tear on all pumps is the same.

ABB (ABBN: SIX Swiss Ex) is a technology leader that is driving the digital transformation of industries. With a history of innovation spanning more than 130 years, ABB has four customer-focused, globally leading businesses: Electrification, Industrial Automation, Motion, and Robotics & Discrete Automation, supported by the ABB Ability™ digital platform. ABB’s Power Grids business will be divested to Hitachi in 2020. ABB operates in more than 100 countries with about 147,000 employees. www.abb.com