Length Matters for Drive to Motor Cables

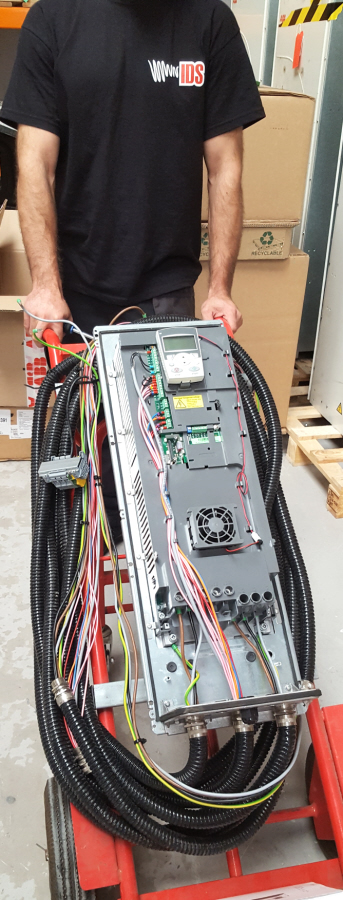

In the ABB Ask the Expert Series, Blaise Ford, CEO of Inverter Drive Systems, a member of ABB’s authorised value provider network, writes:

A drive system’s motor cables should ideally be kept as short as possible. But sometimes, long motor cables are inevitable, typically when the driven equipment is located in an environment where it is not possible to place a drive. This includes applications such as pumps in a hazardous area.

It is perfectly feasible to use long motor cables, with the following considerations:

Get the dimensions right

An AC drive cable only needs to be sized for the motor full load current plus overload. Most sizing software programs assume that a 600% direct-on-line starting current will be required. However, such high currents are unlikely when using AC drives. To avoid over-dimensioning, a resistive load should be selected in the sizing software.

Work out the voltage drop

A motor under AC drive control will only draw a current equal to the full load current plus a possible margin due to any overtorque requirement, with an allowable volt drop of perhaps 4%.

Watch that capacitance

Capacitance coupling between the conductor and the screen, especially at high frequencies, can cause a substantial current in the earthed screen, which may result in a level that overloads the EMC filter components of the drive. It is important to remember that capacitance is due to the total route length of cables. For example, the capacitance for two parallel cables is twice that for a single cable.

Check the cable type

In an industrial environment, steel wire-armoured cable is generally sufficient to maintain the Faraday Cage required for EMC compliance. Use three-core symmetrical cable and limit the maximum cable size to 185 mm sq. for a single cable. Where a greater cross-section is required use parallel cables.

Make sure the earthing/grounding is correct

It is important that the interference returns to its source directly, rather than by stray paths. The motor cable armour/shield and the external earth cable will be correctly grounded when connected to the ground (protective earth (PE)) terminals of the VSD and motor, with no intermediate connection to earth along the cable route. Safety earthing/grounding is then achieved by making a cross-bond from the AC drive ground (PE) to the cubicle earth.

Use suitable filters

Du/dt filters will reduce the rate of change of the voltage pulses mitigating the effects of long cables. Sine filters, meanwhile, are designed to produce a completely sinusoidal waveform, with no distance limitation.

If you have further queries regarding Drive to Motor cables then get in touch, call 0115 944 1036 or email [email protected]