Variable Speed Drive Training

VARIABLE SPEED

DRIVE TRAINING

As a Value Provider for more than 25 years, IDS has grown with the market leading manufacturer ABB. From the legacy drives to the current active products, IDS has supported all the Low Voltage products enabling our team to not only have years of experience, but a full range of training tools acquired along the way.

List of Training by product

ACS180 – Machinery Drive – 0.25kW to 22kW

ACS180 – Machinery Drive – 0.25kW to 22kW

ACS380 – Machine Builders (panel) – 0.25kW to 22kW

ACS480 – General Purpose (Cabinet) – 0.75kW to 22kW

ACS580 – General Purpose – 0.75kW to 500kW

ACH580 – HVACR (Building FM) – 0.75kW to 500kW

ACQ580 – Water & Wastewater – 0.75kW to 500kW

ACS880 – Premium Drive – 0.55kW to 500kW

ACS800 – Legacy Industrial Drive – 0.55kW to 500kW

ACS550 – Legacy General Purpose Drive – 0.75kW to 355kW

ACH550 – Legacy HVAC Drive – 0.75kW to 355kW

ACS355 – Legacy Machine Drive – 0.37kW to 22kW

Other Training

Other Training

Energy Champion – Understand where savings could be achieved. Discussions on Power Quality, Power Factor and Harmonics.

ABB DriveSize – Software based sizing/dimensioning tool for ABB Drives

ABB MotSize – Software based sizing/dimensioning tool for ABB Motors

ABB Motor Optimizer – Web-based software sizing tool for ABB motors

ABB Drive Composer – Startup, commissioning and maintenance tool

Introduction to Drives

New employees into your business will go through a steep learning curve to understand your procedures and processes. They will be furnished with uniforms, laptop, phones and tools to enable them to deliver on the everyday tasks.

IDS offer a service to ‘Induct’ new engineers and apprentices on the Do’s and Don’ts with Drives. Some of our customers have this course as part of their induction process for new joiners.

Contents of this course

- Drive Overview – What are they, what do they do?

- Drive Safety – PPE, isolation, test for dead and areas of danger

- Basic Fault-finding – Visual inspection, bridge testing & triage

- Taking Parameter Backups

- Instigating a call out from IDS.

Fundamental Course

This course is the first in a ‘Drives Journey’ for engineers who will be responsible to maintain these units as part of their duties. Although we use ABB products to deliver the course, not all elements are brand unique and are considered as Drive Best Practice.

This is a 1-day introduction to Variable Speed Drives (VSD) and forms a good foundation for anyone who will come into contact with VSD’s. It is and interactive day with lots of ‘Hands On’ tasks which is supported by some presentations. The content has been put together with the input from the ABB Training School (issue of the Student Guide).

We can also provide refresher training for previous course attendees.

Course Content

Introduction to Variable Speed Drives

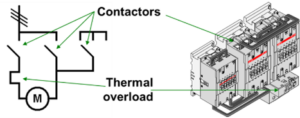

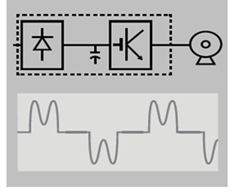

Introduction to Variable Speed Drives- Basics of AC Motors & Starting Methods

- Synchronous Reluctance Motors (SynRM) IE5 Class

- Variable Torque, Constant Torque Applications & Energy Saving

Product Overview and features

Product Overview and features- Practical Tasks – Basic Drive Commissioning, Nominal Values and using the ‘Wizards’. Running the Drive via keypad and from remote switching (I/O). Scaling analogue signals, fault reset manually and auto reset, creating backups and restore.

- Fault-finding. Drive fault codes, what do they mean and where can I find more information. Bridge testing – knowing if you can reset power if a VSD had tripped the supply power.

Extra upon request

- Practical – Strip a motor and discuss the working parts

- Practical – Motor testing (meggering). The correct sequence and discuss the results (are good or bad)

The aim of this course is to provide confidence when attending a VSD and know what and how to react in a breakdown situation. We cover lessons learned from experience and a few trade tips to make this box of tricks your eyes and ears on motor applications.

Those that attend always provide great positive feedback.

No pre-requisites for this course, it’s also a great re-fresher.

Intermediate Course

Second part in the ‘Drive Journey’. We expect delegates already to be able to run a basic commission on a VSD and input nominal values into the VSD without support. This element is a half-day session where a refresher on Drive Safety is then followed by more practical tasks on the training units. We focus on the second part of the ‘Student Guide’ based on the product type.

Second part in the ‘Drive Journey’. We expect delegates already to be able to run a basic commission on a VSD and input nominal values into the VSD without support. This element is a half-day session where a refresher on Drive Safety is then followed by more practical tasks on the training units. We focus on the second part of the ‘Student Guide’ based on the product type.

Course Content

- Commission Drive – Unsupported by trainer

- Perform drive backup and restore (best practice)

- Practical Tasks – Features section of the student guide (product dependant).

- Practical understanding of Scalar and Vector Control.

Discussion on Comms and BMS integration.

Discussion on Comms and BMS integration.- Fieldbus additions to the VSD. Extra I/O, Comms selection, Plus Codes.

- Fault-finding. Trainer will instigate a fault. Delegate to restore drive explaining the fault type and use the correct procedure to recover unit.

- Introduction to Harmonics with VSD’

Extra upon request (extend to 1 day session)

Drive replacements – Considerations, ventilation, environment, drive selection, discrimination and de-rating.

Drive replacements – Considerations, ventilation, environment, drive selection, discrimination and de-rating.- Software – Using Drive Composer

- LifeCycle Management – Manage your Assets as recommended by the manufacturer.

The aim of this course is to build confidence when attending a VSD. This is more of a learner led session where the trainer will step back from teaching each element and allow the delegate to ‘work it out’

Pre-requisites for this course, the delegate must have attended the Fundamental Course first.

The delegate will have an all-round understanding of the drive product type, have full confidence when interrogating the menu structure, be confident to replace and commission a VSD in scalar and vector. control modes. Knowledge of the accessories and plus codes to ensure the full benefits of the drive.

Advanced Course

The third and final part of the ‘Drive Journey’. The delegate has already completed the fundamental and intermediate courses, now is the time to really make the VSD dance!

The third and final part of the ‘Drive Journey’. The delegate has already completed the fundamental and intermediate courses, now is the time to really make the VSD dance!

Delivered by ABB drive specialists this element requires the delegate to bring a laptop with Drive Composer installed. ABB modern drives hold PLC’s and PID loop  controllers onboard enabling further specialist tasks to be carried out by the drive, negating the need for a centralised PLC or have the drive support the PLC, if failure happens.

controllers onboard enabling further specialist tasks to be carried out by the drive, negating the need for a centralised PLC or have the drive support the PLC, if failure happens.

Pitched at ICA and PLC engineers for a full 1-day training experience

Course Content

Commission Drive – Unsupported by trainer

Commission Drive – Unsupported by trainer- Perform drive backup and restore (best practice)

- Practical Tasks –the ABB trainer will expect the delegate to already have a full and deep understanding of VSD commissioning before briefing on Functional Block programming.

- Practical Tasks – Perform various logic-controlled tasks via the imbedded Adaptive Program (AP) function of the drive

- ACQ580 – Intelligent pump control (IPC). Configure duty, standby, assist via IPC control.

Extra upon request (extend to 2-day session)

Drive replacements – Considerations, ventilation, environment, drive selection, discrimination and de-rating.

Drive replacements – Considerations, ventilation, environment, drive selection, discrimination and de-rating.- LifeCycle Management – Manage your Assets as recommended by the manufacturer.

The aim of this course is to enable ICA and PLC engineers to use the imbedded functions of the modern ABB drive. Initialise a process before the VSD drives a motor/pump.

Pre-requisites for this course, the delegate must have attended the Fundamental and Intermediate courses first

The delegate will have an all-round understanding of the drive product type, have full confidence when interrogating the menu structure, be confident to replace and commission. Installing an AP program providing further functionality to the process.

Customised Training

Our training can be planned and bespoke to your company needs. Some engineers will attend the fundamental course several times and feel that is all they require to keep their assets in best performance on a daily basis, anything else and IDS can attend.

If you want to produce a training program that suits your business needs, then please contact sales@inverterdrivesystems.com for more information.

Further Courses Available

- Energy Champion – empower an interested employee to seek out energy saving opportunities in your business. This course will provide a system to see which motor applications could save energy and money. It is a 2-day course with several presentations and some interactive surveying. The aim is to support the delegate in providing energy saving reports which will have returns on investment figures (ROI).

- ABB DriveSize – ABB software used to configure from transformer through to motor the correct dimensioning considerations and provide a desktop on harmonic effects, cable sizing and environmental conditions.

- ABB MotSize – A PC program to help select an optimal low voltage Direct Online (DOL) motor. In MotSize the user can define several selection options like IE class, MEPS etc. to find a suitable catalogue motor. MotSize supports several types of data sheets, graphical printouts and documentation. MotSize motor databases are frequently updated to always offer the latest available motors.

- ABB Motor Optimizer – Is an online tool that helps you to find the optimal electrical motor for any MEPS worldwide. Compute the cost of ownership of different motors and get fast access to marketing documents and drawings, test reports and data sheets.

- ABB Drive Composer – Is a start-up and maintenance tool for ABB’s common architecture drives. The tool is used to view and set drive parameters, and to monitor and tune process performance. The entry version of Drive Composer provides basic functionality for setting parameters, basic monitoring, taking local control of the drive from the PC, and event logger handling. The entry version is available for free and can be downloaded.

Drive Composer pro is the full-fledged commissioning and troubleshooting tool. Order Drive Composer pro from IDS. Existing license holders can upgrade to latest version of Drive Composer pro by downloading the installation package.

Let's Talk

Whether you want to explore better process control, discover just how much energy can be saved with inverter technology or if you have a non-urgent technical query, please complete the form and one of our engineers will be in touch soon.

Alternatively, call 0115 944 1036 for 24/7 breakdown support or email sales@inverterdrivesystems.com