How Variable Speed Drives help towards Net Zero

As our world accelerates towards a more sustainable future, the significance of variable speed drives (VSDs) in our journey to net zero cannot be overstated. Currently, electric motors are the powerhouse behind over 45% of global electricity consumption. By 2040, their numbers are projected to double, placing energy efficiency at the forefront of the global agenda.

Contents:

- The Net Zero Challenge

- The Role of Energy Efficiency

- Industry’s Inefficiency

- The Efficiency of VSDs: Harnessing Technology for Sustainable Operations

- Load Profiles and Energy Savings: The Impact of VSDs

- Success Story: The Transformative Power of VSDs

- Regenerative VSDs: Green Energy Generation and Sustainability

- The Directive and Motor Efficiency: Steering Towards a Greener Future

- VSDs: Control Philosophy and Maintenance – Maximising Efficiency and Longevity

- Motor Selection: Efficiency and Sustainability – Strategic Approaches for Optimal Performance

- Partner with IDS for a Sustainable Future

The Net Zero Challenge

With many industries, including the UK water sector, aiming to achieve net zero by 2030, the reduction of operational GHG emissions is paramount. Offsetting residual emissions remains a strategy, with a preference for UK-based projects supported by government policies to fortify the local offset market.

The Role of Energy Efficiency

According to the IEA Sustainable Development Scenario, energy efficiency is responsible for more than 40% of the emissions abatement required by 2040. It’s seen as the ‘first fuel’ in the global effort to manage consumption while supporting growth in emerging economies.

Industry’s Inefficiency

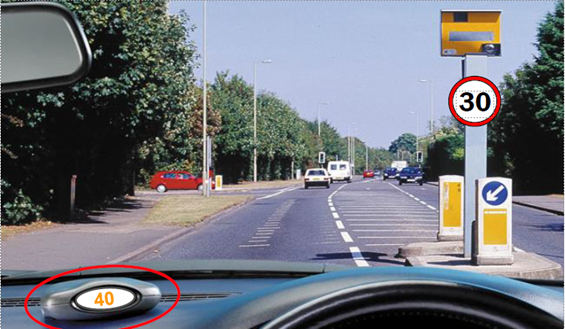

In this scenario, when a car approaches a speed limit reduction, the logical action is to decelerate. By removing your foot from the accelerator and braking to reduce speed.

However, industry often continues at full speed, relying on ‘braking’—a method that is anything but efficient.

The ‘Braking’ Approach to Energy Management

The approach many industries take towards energy management can be metaphorically compared to a driver speeding towards a reduced speed zone and choosing to brake at the last moment rather than slowing down in advance. This ‘braking’ method, prevalent in various sectors, is indicative of a reactive rather than proactive approach to energy consumption.

Understanding the ‘Braking’ Method In industry, the ‘braking’ method is akin to operating equipment at full power regardless of the actual demand and then applying energy-intensive methods to curb the output when necessary. It’s like pressing hard on the accelerator only to rely on brakes to manage speed instead of easing off the accelerator according to the speed limit.

The Cost of Inefficiency This approach is not only inefficient but also costly. It leads to higher energy consumption, increased wear and tear on machinery, and greater operational costs due to the energy wasted when machines are not operating at optimal speeds for their loads. The analogy extends to increased maintenance costs and downtime, akin to the wear on a car’s brakes and engine due to inefficient driving habits.

The Incongruity with Net Zero Goals Such a strategy is incongruous with the global push towards net zero emissions. In the race to reduce carbon footprints, a ‘braking’ approach is counterintuitive. It overlooks the potential for substantial energy savings and carbon reduction that could be achieved with a more nuanced, variable approach that adjusts power usage to actual demand.

The Contrast with VSDs Variable Speed Drives (VSDs) offer an alternative that mirrors the anticipation a driver uses when approaching a known speed limit reduction. Instead of the jarring stop-start of traditional industrial practices, VSDs provide a smooth transition of power supply, adjusting the motor speed in real-time according to process needs. This not only conserves energy but also reduces mechanical stress and extends the life of equipment.

The Call for a Paradigm Shift The metaphor of industry’s ‘braking’ inefficiency is a call to action. It highlights the need for a paradigm shift in how energy is managed—a shift from reactive braking to proactive, intelligent speed control. It’s a move towards synchronisation of industrial operations with the rhythms of demand, rather than the inefficient status quo.

The metaphor serves as a stark reminder of the need for industries to adopt more efficient and sustainable practices. By moving away from the ‘braking’ method and embracing technologies like VSDs, industries can significantly reduce their energy consumption and carbon emissions, paving the way for a more sustainable and economically sound future.

The Efficiency of VSDs: Harnessing Technology for Sustainable Operations

Variable Speed Drives (VSDs) stand as a modern-day industrial revolution in the realm of energy efficiency. The adoption of these innovative devices can lead to a paradigm shift in how energy is consumed and managed across various applications, particularly in systems that traditionally operate at constant speeds regardless of demand.

Understanding VSDs VSDs are electronic control devices designed to control the speed and torque output of electric motors. They function by adjusting the voltage and frequency supplied to the motor, allowing it to run at speeds that precisely match the operational requirements of the process or application they are controlling. This fine-tuning capability is crucial for avoiding the wasteful consumption of electricity that occurs when motors run at full capacity unnecessarily.

Significant Energy and Carbon Savings The efficiency gains from VSDs are substantial. In centrifugal applications such as fans, pumps, and compressors, VSDs can cut energy usage by up to 50% for just a 20% speed reduction. This not only translates to lower operational costs but also equates to significant reductions in carbon emissions. In an age where every watt of electricity and every kilogram of CO2 counts towards global sustainability goals, the impact of VSDs is profound.

ROI and Financial Incentives The financial incentives for adopting VSDs are equally compelling. Return on investment (ROI) is a critical measure for any capital expenditure, and VSDs typically boast an ROI period of less than 1-2 years. This rapid payback is a result of the immediate energy savings and subsequent cost reductions in utility bills.

Beyond Energy Savings VSDs contribute to sustainability beyond mere energy savings. They reduce mechanical stress on motors by providing soft start capabilities, which reduces the wear and tear on mechanical components and extends the lifespan of the equipment. Additionally, VSDs offer better protection for motors and more sophisticated control options, which can lead to improved process control and quality.

Control Philosophies and Load Adaptation The true value of VSDs is realised through their adaptability to different load profiles. Whether dealing with constant torque or variable torque loads, VSDs adjust the motor’s operation to match the required torque, thereby conserving energy. In variable torque applications, this is particularly effective as the power required can be significantly less at reduced speeds, resulting in exponential energy savings.

The efficiency of VSDs is not just about conserving energy; it’s about redefining operational excellence. It encompasses a holistic approach to energy management, enhancing performance, reducing costs, and contributing to environmental sustainability. With VSDs, industries have the power to modernise their operations, achieve their net-zero targets, and create a more sustainable future.

Load Profiles and Energy Savings: The Impact of VSDs

The concept of load profiles is pivotal when discussing the energy efficiency of motor-driven systems. Load profiles refer to the operational patterns of these systems, specifically how the demand for torque varies with speed. There are two principal types of load profiles—constant torque and variable torque—which can both significantly influenced by the application of Variable Speed Drives (VSDs).

Constant Torque Applications: In constant torque applications, the torque requirement remains unchanged regardless of speed. Examples include hoists, conveyors, and compressors. In these scenarios, VSDs provide benefits by adjusting motor speed to the precise needs of the application, avoiding energy waste during periods of lower demand.

Variable Torque Applications: Variable torque applications, common in equipment such as pumps and fans, require more torque as the speed increases. This is due to the nature of centrifugal loads where the power needed is proportional to the cube of the speed. Here, the energy-saving potential of VSDs is even more pronounced. By adjusting the motor speed to align with the actual demand, rather than running at full speed, VSDs can achieve significant reductions in energy consumption.

Energy and Carbon Savings Illustrated: The impact of VSDs on energy and carbon savings can be substantial. Consider the process of emptying or filling a tank using a pump. Operating the motor at full speed consumes a certain amount of energy and results in a corresponding CO2 emission. However, by employing a VSD to run the motor at 80% speed, the flow is reduced, but the energy consumption is disproportionately less, leading to energy and carbon savings. For instance, a pump that might use 100kW at full capacity could only require 50kW when the flow is reduced by 20%, thereby cutting energy usage and costs by over 35%, along with a similar reduction in CO2 emissions.

Practical Examples: A real-life application in a 110kW fan system demonstrates the benefits of this approach. By reducing the speed by just 0.5Hz, there’s a 3% energy saving per 1% speed reduction, equating to more than £5000 and 6 tonnes of CO2 saved annually. On a larger scale, a 1Hz speed reduction can lead to a 6% energy saving, showcasing that even incremental adjustments can have a significant impact.

The intelligent application of VSDs to different load profiles not only enhances energy efficiency but also contributes to an organisation’s carbon reduction targets. These savings are critical for businesses looking to improve their bottom line while also making a positive impact on the environment.

Success Story: The Transformative Power of VSDs

The implementation of Variable Speed Drives (VSDs) has a proven track record of substantial energy and cost savings across various industries. The experiences of businesses like Village Urban Resorts underscore the tangible benefits of embracing this technology.

Village Urban Resorts: A Case Study in Efficiency Village Urban Resorts’ journey to energy efficiency provides a compelling success story. In collaboration with Consult Maskell and ABB, the hotel chain embarked on a mission to reduce its energy consumption. The initial trials with VSDs on their air handling units yielded promising results that led to a significant decision: full-scale implementation across the group.

After installing inverters on air handling units, pool, and spa pumps, the energy costs plummeted. Village Urban Resorts witnessed a 49% reduction in energy expenditure, translating to an annual saving of nearly £500,000. The environmental impact was equally impressive, with a reduction of nearly 5,000,000 kWh in energy use and a cut down of 2770 tons of CO2 emissions.

Impact on Carbon Footprint The installation of VSDs also led to a dramatic decrease in the carbon footprint of the hotels. By controlling the air flow more efficiently, the total kWh used per year on both motors was reduced by 115,000 kWh. This saving is equivalent to turning off 315 x 100W lamps for 10 hours every day for an entire year, demonstrating the significant environmental impact that can be achieved through energy efficiency measures. The carbon savings translated to 85 tonnes of CO2, a substantial contribution to the fight against climate change.

Wider Adoption and ROI Encouraged by the success at the Village Urban Resort in Walsall, the chain approved the installation of VSDs across 19 of its 27 sites. The predicted cumulative savings amounted to around 5,000,000 kWh of electricity, costing just under £500,000. Remarkably, the return on their investment was realised in under 12 months—a testament to the financial viability of investing in energy efficiency.

This success story serves as a powerful example, showcasing the benefits of VSDs in reducing energy consumption, operational costs, and greenhouse gas emissions. They provide compelling evidence for other businesses considering such investments, illustrating that the upfront costs of installing VSDs are quickly offset by the substantial savings and environmental benefits.

Regenerative VSDs: Green Energy Generation and Sustainability

Regenerative Variable Speed Drives (VSDs) take the potential of energy-saving technology a step further by not only conserving energy but also generating it. This transformative capability allows industries to become active participants in sustainable energy solutions.

Green Energy Generation at Lower Glendevon Reservoir A prime example of regenerative VSDs in action is the installation at the Lower Glendevon reservoir. Here, a hydroelectric generation solution comprising a reversible-pump turbine, a generator, and a regenerative VSD has been installed. This system does more than just manage the flow and control of the water—it also generates renewable electricity. The design is such that while fulfilling the reservoir’s primary purpose of providing water flow, it concurrently produces clean energy. This energy is not only used for the reservoir’s own needs but is also fed back into the grid, supplying power to approximately 100 local homes.

Carbon Savings and Environmental Impact The environmental impact of this installation is noteworthy. Within the first three months of operation, the system generated over 113,000 kWh of electricity, which was returned to the grid. This contribution is set to save at least the equivalent of 93 tonnes of carbon dioxide annually, according to Tom Coutts, Senior Project Manager for TSSE. Such figures highlight the dual benefits of regenerative VSDs: they support the local infrastructure and contribute to carbon reduction initiatives.

Financial Implications and ROI Aside from the environmental advantages, regenerative VSDs also make financial sense. The cost savings are significant when compared to traditional energy sources. By generating their own power, facilities like Lower Glendevon can achieve a reduction in energy costs and enjoy a fast return on investment, often within a single year. This efficiency turns a necessary operational expense into a source of income, providing a strong incentive for businesses to invest in regenerative technologies.

Innovation and Future Potential The case of Lower Glendevon reservoir is just one instance of how regenerative VSDs can be integrated into existing systems to provide greener and more cost-effective energy solutions. It is a model that can be replicated in various settings, including industrial applications where excess mechanical energy can be harnessed and converted into electrical energy, thus contributing to the circular economy.

Regenerative VSDs represent a significant advancement in energy technology. They are not just reducing consumption but are actively creating energy, closing the loop on energy use, and paving the way towards a more sustainable and self-sufficient industrial environment. The success of these systems serves as a beacon for other organisations to follow, proving that sustainable practices can result in economic gain while also benefiting the wider community and environment.

The Directive and Motor Efficiency: Steering Towards a Greener Future

The European Union’s Eco-design Directive is a key piece of legislation that outlines a clear path for increasing the energy efficiency of electric motors in industrial applications. This directive is not just a set of regulations—it is a strategic roadmap to reduce energy consumption and greenhouse gas emissions, thereby supporting the EU’s commitments to the Paris Agreement and its own ambitious climate goals.

The IE Classification System Central to the directive is the International Efficiency (IE) classification system, which categorises electric motors based on their efficiency levels. These classes range from IE1, indicating standard efficiency, to IE5, which denotes the highest level of efficiency currently recognised.

The Shift to Higher Efficiency Standards Since July 2021, the EU Eco-design Regulation has mandated that most industrial motors meet at least IE3 efficiency standards. These regulations tightened further in July 2023, now motors with a power rating between 75kW and 200kW are required to meet IE4 standards. This progressive tightening of standards reflects the EU’s commitment to continuously drive the market towards greater energy savings and lower carbon emissions.

The Advantages of IE5 SynRM Motors The IE5 SynRM (Synchronous Reluctance Motor) represents the pinnacle of motor efficiency. These motors are designed to reduce energy losses by a significant margin when compared to the IE3 induction motors, which are the minimum standard set by the latest regulations. The use of IE5 SynRM motors can translate to energy savings of up to 20%*, depending on the specific application and operating conditions.

Industrial case studies have demonstrated the substantial energy cost reductions that can be achieved with SynRM motor and VSD packages, compared with the motors they replace. For businesses, this means not just compliance with current regulations, but an opportunity to future-proof their operations against upcoming standards and benefit from associated energy cost savings.

Time for an Upgrade: Embracing IE5 SynRM Motors The directive encourages operators to consider upgrading to ultra-premium efficiency motors. A comparison between a 15-year-old Eff2 motor and a modern IE5 motor illustrates the potential savings: an Eff2 motor, less than 90% efficient, costs considerably more per annum to run than an IE5 motor, which operates at over 95% efficiency. The initial investment in a more efficient motor is quickly offset by these operational savings and the corresponding reduction in carbon emissions.

Evaluating Full and Part Load Efficiency ABB’s research confirms that the SynRM’s efficiency advantage holds not just at full load, but also at partial load conditions. This is crucial, as motors often operate under partial load, where the potential for energy savings is even more significant. Operators can perform payback calculations by comparing efficiencies at nominal and partial load conditions to determine the potential return on investment.

The EU Eco-design Directive is a clarion call for industry to adopt more efficient motors, with VSDs playing a critical role in achieving the desired energy savings. As regulations evolve, the benefits of upgrading to high-efficiency motors such as IE5 SynRM become increasingly clear: reduced energy costs, lower carbon emissions, and compliance with stringent efficiency standards. For businesses ready to take the next step in their energy efficiency journey, the directive serves as both a guide and an incentive to invest in the future of motor technology.

*Note: The exact energy savings depend on the specific application and operating conditions.

VSDs: Control Philosophy and Maintenance – Maximising Efficiency and Longevity

Variable Speed Drives (VSDs) are not just components that can be installed and forgotten. They require a thoughtful control philosophy and diligent maintenance to ensure they operate at peak efficiency throughout their lifecycle. The European Union’s Ecodesign Directive underscores the significance of these aspects by identifying VSDs as a crucial element for achieving energy efficiency, particularly in pump and fan systems.

Control Philosophy: The Art of Precision A control philosophy for VSDs is akin to a set of instructions that dictates how the drive interacts with the motor and the application it controls. It involves defining the parameters and algorithms that determine the motor’s speed and torque in response to varying process demands. This ensures that the motor only uses the energy necessary for the current operational requirement, thereby minimising waste.

For instance, in a wastewater treatment plant, the control philosophy might include PID (Proportional-Integral-Derivative) algorithms to adjust pump speeds and maintain consistent water flow rates. In HVAC systems, VSDs can be set to modulate the operation of air handling units based on occupancy levels or external temperature changes.

Optimisation and Commissioning: Setting the Stage for Efficiency VSDs need to be properly commissioned and optimised to match the specific demands of the application. This involves setting up the VSD with the correct parameters to ensure it runs efficiently and in harmony with the system it controls. Incorrect commissioning can lead to energy inefficiencies, increased wear on equipment, or even system failures.

Maintenance: The Key to Longevity Maintenance of VSDs is another crucial area. Regular checks and servicing help in identifying potential issues before they escalate into major problems. This includes cleaning, checking connections, monitoring heat sinks, replacing fans and capacitors, and ensuring the firmware is up to date. Proper maintenance ensures that VSDs continue to operate efficiently and can extend their operational life significantly.

Monitoring Systems: The Watchful Eye The use of monitoring systems with VSDs can provide real-time data on performance and energy consumption. These systems can detect deviations from expected performance, allowing for immediate corrective actions. They can also help in optimising the control philosophy by providing insights into how the drives are interacting with the system and where improvements can be made.

The Knock-on Effects: Beyond Energy Savings The benefits of using VSDs extend beyond direct energy savings. They contribute to a reduction in maintenance needs due to lower RPMs and less mechanical stress from soft starting capabilities, compared to Direct-On-Line (DOL) starting methods. This also leads to extended equipment life and reduced downtime. Moreover, condition monitoring of the driven system can prevent failures, leading to further savings and efficiency improvements.

VSDs are a critical component for achieving energy efficiency in industrial systems. However, to fully realise their potential, a comprehensive control philosophy must be developed, proper commissioning and optimisation must be conducted, and diligent maintenance practices must be implemented. By focusing on these areas, businesses can ensure that their VSDs contribute to both immediate energy savings and long-term operational efficiency.

Motor Selection: Efficiency and Sustainability – Strategic Approaches for Optimal Performance

In the world of industrial efficiency, motor selection stands as a critical decision point that significantly impacts energy consumption and sustainability outcomes. The drive towards greener operations underlines the importance of choosing motors that not only meet current energy demands but also anticipate future efficiency standards and sustainability goals.

Crafting a Motor Policy: Anticipating the Future A well-conceived motor policy is essential for ensuring the best possible motor efficiency. This policy should set forth guidelines for selecting motors that exceed the minimum efficiency standards where feasible. For example, even though IE3 motors are currently the standard as per EU regulations, forward-thinking organisations might opt for IE4 or IE5 motors in anticipation of future regulations and to achieve greater energy savings.

Repair vs. Replace: The Cost-Efficiency Balance The decision to repair or replace a motor is a pivotal one. A robust strategy should weigh factors such as carbon footprint, cost, lead time, and efficiency. In many cases, replacing an older, less efficient motor with a new high-efficiency model can lead to significant energy savings that justify the initial investment. Conversely, repairing an older motor may be more cost-effective in the short term but could result in higher operational costs and a larger carbon footprint over time.

Unexpected Failures: Making Informed Choices When a motor fails unexpectedly, the pressure to resume operations can often lead to hasty decisions, such as choosing a like-for-like replacement or opting for a quick rewind. However, these choices may not align with the best long-term efficiency outcomes. Developing a policy that accounts for such scenarios can help ensure that decisions made under pressure still support efficiency and sustainability objectives.

New Installations: The Importance of Whole Life Cost With new installations, there’s a tendency to focus on the upfront cost rather than considering the whole life cost of the motor. This perspective can overlook the significant energy and cost savings that more efficient motors can offer over their operational lifespan. Procurement processes and KPIs should be aligned to support the selection of high-efficiency motors that will deliver lower total costs and emissions over time.

Targeting End-of-Life Motors: Timely Replacements Focusing on motors that are nearing the end of their operational life offers an opportunity for timely upgrades. Replacing these motors with high-efficiency models is not just an investment in energy savings; it’s often a necessary step that can prevent downtime and inefficiencies associated with end-of-life equipment.

Strategic motor selection is a key factor in the pursuit of energy efficiency and sustainability. It requires a comprehensive approach that considers not only the immediate needs but also the long-term performance and cost implications. By adopting a forward-thinking motor policy, organisations can make informed decisions that align with their efficiency goals and environmental commitments, ultimately leading to a more sustainable future.

Partner with IDS for a Sustainable Future

The journey to a sustainable future is not a solo endeavour; it requires collaboration, expertise, and decisive action. At IDS (Inverter Drive Systems Ltd), we invite you to join forces with our team of dedicated engineers who are ready to propel your operations towards greater energy efficiency and a smaller carbon footprint.

Tailored Solutions for Your Business Each business is unique, with its own set of challenges and opportunities. Our engineers are adept at understanding these nuances and delivering customised solutions that meet your specific needs. Whether it’s upgrading to the latest motor technology, optimising VSDs for your processes, or implementing a full-scale energy efficiency retrofit, IDS has the expertise to make it happen.

Take the First Step Contact IDS today to schedule a consultation. Let us guide you through the options, from selecting the right motors and drives to implementing a comprehensive energy-saving strategy. Our team is eager to work with you, offering professional advice, exceptional service, and the support you need to achieve your sustainability goals.