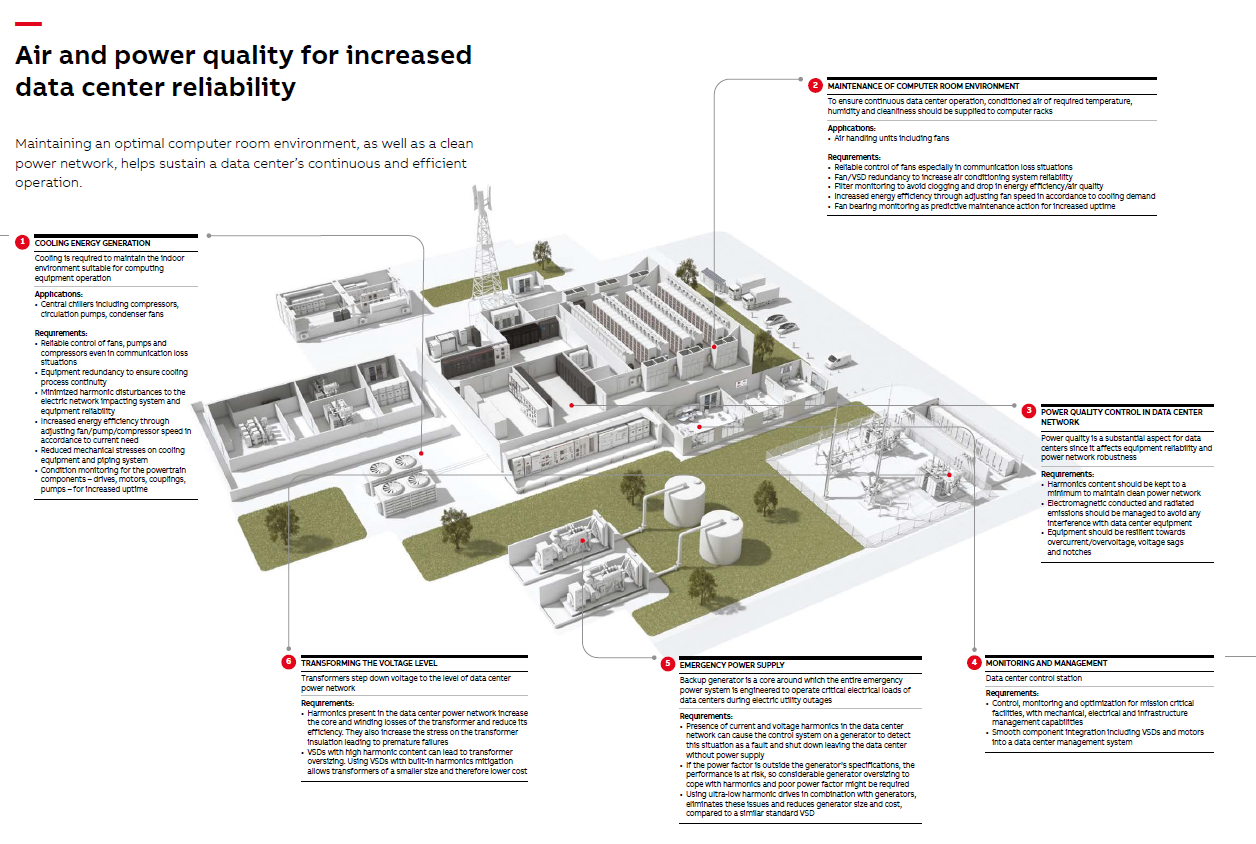

Data Center Cooling

Taking uptime, sustainability and energy efficiency to a new level.

Improving data center performance through efficient energy use, increased reliability and advanced maintenance.

The world depends increasingly on data, computing power and connectivity, making data centers mission-critical facilities requiring special attention. ABB provides data centers with reliable, flexible and secure operation. Its solutions ensure continuous availability while helping to improve performance in a productive and sustainable way.

System reliability and process continuity

Tackle air conditioning demands…

- Air conditioning is critical for server operation due to IT equipment’s sensitivity to heat, humidity and dust.

… using best-in-class technology

- ABB’s variable speed drives (VSDs) help maintain a favorable environment to avoid server failures and maximize IT equipment uptime.

- With ABB’s standby generators, power is always available for servers and engineering systems during emergency situations.

Conform to industry standards…

- Data center equipment and engineering systems must meet the highest levels of infrastructure reliability and redundancy to sustain continuous operation.

… with solutions that build trust

- ABB’s VSDs, motors and generators meet data centers’ highest reliability and security standards.

- Ultra-low harmonic drives comply with the strictest harmonic requirements to eliminate power quality issues.

- Drives’ compliance with power-loss-ride-through standards secures operation during short power outages.

- VSDs withstand high vibrations fulfilling seismic standards of international building codes to ensure smooth data center operation even during earthquakes.

Energy efficiency and sustainability

Find the big energy users…

- On average, the cooling system accounts for 40 percent of energy consumed by a data center.

- Server load varies depending on multiple factors and the cooling system must adjust accordingly.

- Power usage effectiveness (PUE) is a ratio of the total power consumed by a data center to the power consumed by IT equipment. The more efficient the data center’s engineering networks, the closer is the PUE to 1.

… and unlock the saving potential

- VSDs replace throttling or bypass valves for better flow control, resulting, on average, in 20 to 60 percent energy savings for the air conditioning system, while improving the data center’s PUE.

- Upgrading to IE4 or IE5 efficiency class motors significantly reduces energy consumption.

• ABB AbilityTM Smart Sensors for motors, as well as VSD energy counters, help analyze energy use and implement improvements for the entire system.

Security

Capitalizing on the digital era…

- Modern automation and control systems are often interconnected, which makes them vulnerable compared to isolated systems. Cloud connection further adds to a system’s vulnerability.

- Denial-of-Service (DoS) attacks and malware are all too common and have already impacted industrial control systems.

- VSDs enable remote (wired and wireless) operation and monitoring capabilities which increases the importance of hindering unauthorized access to automation systems.

… with data-secure solutions for processes and applications

- For VSD cyber security, parameter value change and software loading can be protected by a password.

- ABB software tools establish communication only with “recognized devices” like ABB VSDs or gateways.

- The ABB Ability™ Condition Monitoring for drives and remote assistance services meet strict cyber security standards in compliance with ABB test and verification procedures.

- As a member of IEEE and IEC, ABB recognizes the importance of cyber security standards. It makes sure that the needs of customers are considered when developing new standards. ABB also incorporates new standards into its products and systems, helping customers comply with upcoming regulations.

Operation and maintenance

Eliminate operating process risks…

- Data center shutdowns are costly and result in business disruption and reputation damage.

… by utilizing smart functionality

- Temperature, overload, overcurrent, under/overvoltage and other protection features and warnings within VSDs help prevent failures in air conditioning system control.

- A VSD’s real-time clock allows timed tracking of faults, so you know what happened and when.

- Ultra-low harmonic drives protect power quality in the data center network, making the power system and equipment more resilient.

“How can I control rising costs?”

Lower operational overheads…

- Operational costs can be optimized without compromising data center operation continuity.

… through advanced solutions and maintenance regimes

- Ultra-low harmonic drives save money by maintaining unity power factor and therefore eliminating reactive power penalties from the utility.

- ABB Ability™ Condition Monitoring service delivers realtime information about VSD and motor events and proposes targeted maintenance actions when needed, eliminating regular inspections.

- ABB Ability™ Energy Optimization for drives and motors analyzes the energy savings potential in data centers.

• Global service network and preventive maintenance contracts relieve pressure on in-house teams and increase speed of response to critical issues.

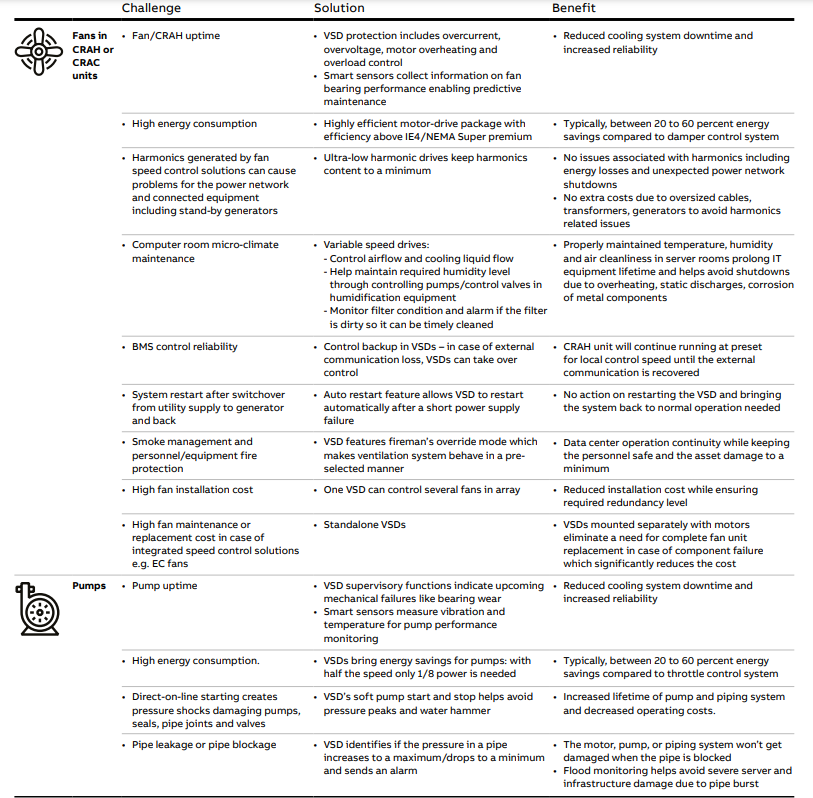

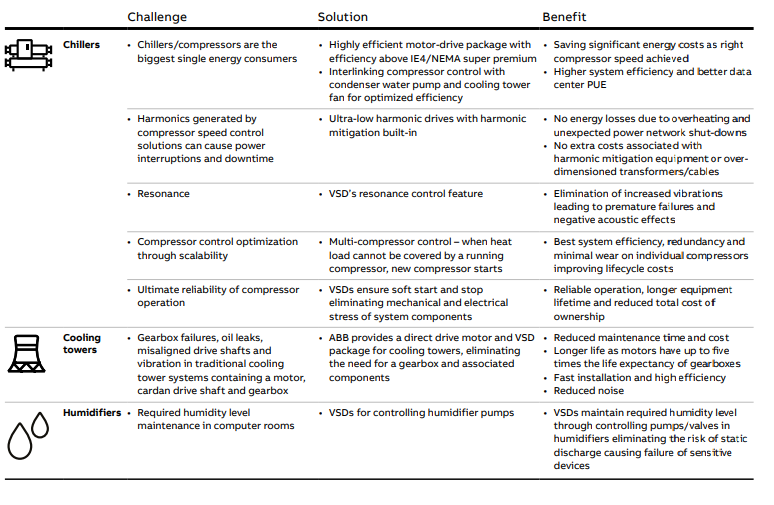

Unlock the potential of data center cooling applications

Alongside cooling reliability, energy savings and security, there are many other benefits from using variable speed drives and high efficiency motor technologies on motor-driven applications.

Features and functions benefiting data centers

VSDs, motors and generators all play a vital role in keeping fluids moving in air conditioning systems. Choosing the right product features for such a demanding sector as data centers is essential in ensuring reliable and efficient operation while minimizing risks.

Variable speed drives

Built-in redundancy

- External communication loss is handled seamlessly by VSD taking control. Application continues running in preset for local control mode until the external communication is recovered.

Protection features and robustness

- Coated boards, earth fault protection, overcurrent and undervoltage control contribute to cooling process reliability. Every VSD is factory tested, verifying its performance.

Low harmonics

- Built-in active supply unit and integrated low harmonic line filter eliminate power supply disturbances that can interrupt data center operation.

Security

- Parameter value change and software loading can be protected by a password as part of VSD cyber security.

Energy efficiency

- Energy Optimizer feature improves energy use further by reducing motor iron losses.

Support of various communication protocols

- Communication capability ensures VSDs are integral part of a data center management system.

Flying start

- Reduces wear and saves time by starting a motor while the load is still spinning.

Automatic restart

- VSD restarts automatically after a short power supply outage e.g. when switching from utility supply to generator and back.

Motors

High reliability

- Protection against external conditions with IP55 as standard.

- Surface treatment according to corrosion class C3M and optional C4 and C5.

- Protection against bearing currents with an extended portfolio of solutions including insulated bearings and shaft grounding.

- Bearings either greased for life or regreasable, fitted with grease relief system.

- Bearings locked at D-end to avoid axial play.

Efficiency

- IE3, IE4 or IE5 efficiency levels to reduce energy consumption and improve total cost of ownership.

Easy installation

- Oversized terminal box as standard to ease installation.

- Various mounting arrangements including direct drive, belt or transmission.

ABB AbilityTM Smart Sensors

Smart Sensor for motors

- Converts traditional motors into smart, wirelessly connected devices.

- Picks up data on vibration, temperature and other parameters to gain information on motor overall performance.

- Helps to identify potential for energy savings, reduce risks related to unexpected breakdowns, extend equipment lifetime and lower maintenance costs.

Smart Sensor for pumps

- Measures vibration and temperature from the surface of the pump to gain information on the pump’s performance.

- Based on the measurements, health indicators for detecting cavitation, bearing failure, blade problems, looseness, unbalance or overheating are calculated.

Smart Sensor for mounted bearings

- Monitors the health of ABB Dodge mounted bearings, to reduce downtime, improve reliability and operate safely.

Generators

High reliability

- Meet demands for low voltage ride-through events, vibration, mechanical and electrical stresses, fast response times and frequent starts.

- Improve the quality of an electricity supply reducing harmonic content.

Efficiency

- Reduced fuel consumption for a longer operation in emergency situations.

Compactness

- The best kWh production at given size and weight.

Wide offering

- Available over a large range of operating parameters and enclosures, complying with all internationally accepted standards.

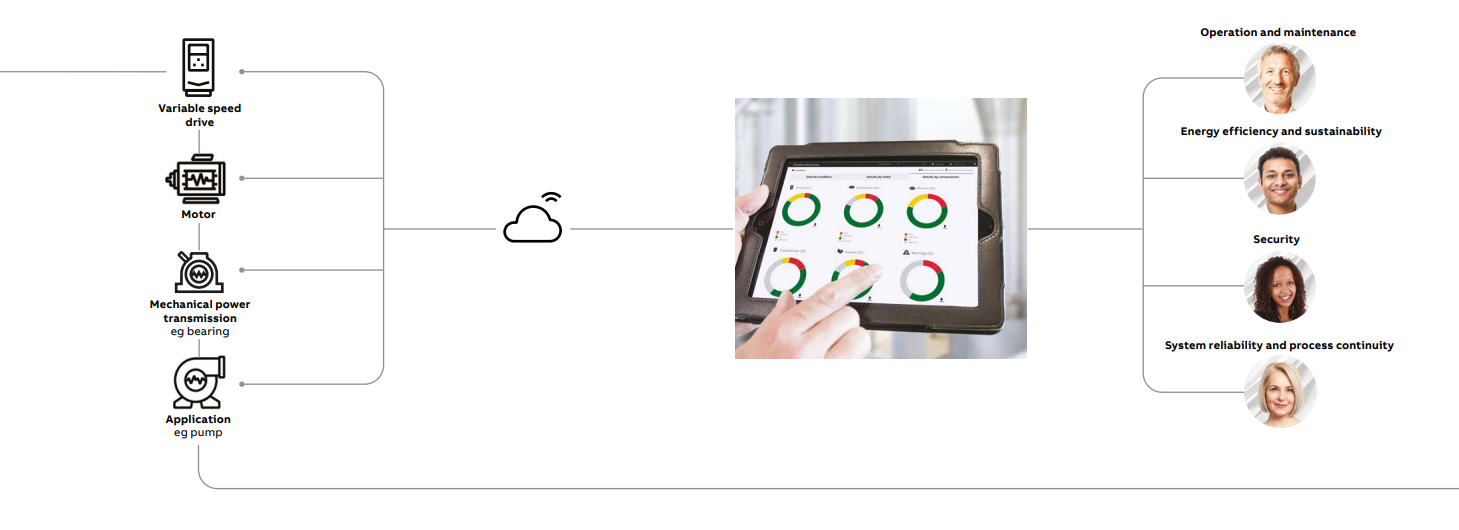

From the facility to the cloud and beyond

ABB Ability™ Condition Monitoring for powertrains optimizes the performance and efficiency of rotating equipment. It enables full transparency on all parameters for VSDs, motors, mounted bearings and applications like pumps.

Intelligent powertrain

The powertrain is equipped with sensors and cloud connectivity and can comprise motors, drives and mechanical components including bearings, couplings and applications like pumps.

Turning data into valuable information

Data gathered from VSDs’ built-in sensors and loggers, together with that collected from ABB Ability™ Smart Sensors fitted to motors, bearings and pumps, can be collated, stored and further accessed via the cloud. The ability to gather and analyze this data can reveal information on the status and condition of your equipment, so that you can schedule proactive service.

Accessing data for analytics

You have access to a monitoring portal to view key operational parameters of individual assets as one unified system. Detailed dashboards give full transparency so that you can take actions that lead to less downtime, extended equipment lifetime, lower costs, safer operations and increased profitability.

Gain a digital advantage

Ensuring that the right person has the right information at the right time brings:

- Appropriate response to process challenges, minimizing operating costs.

- Greater insight into various aspects of the process, thereby improving system performance.

- Lower risk of process failure and change the maintenance from reactive to predictive.

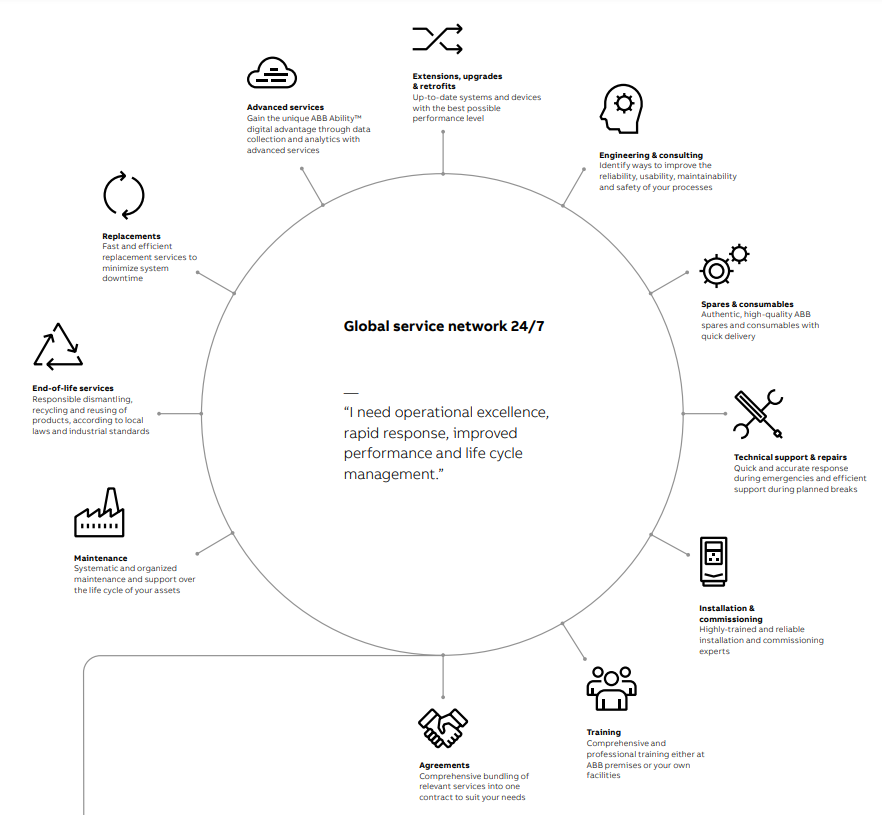

Keep your facility running

From spare parts and technical support to cloud-based remote monitoring solutions, ABB offers the most extensive service offering to fit your needs. The global ABB service units complemented by external Value Providers form a service network on your doorstep. Maximize performance, uptime and efficiency throughout the life cycle of your assets.

With you every step of the way

Even before you buy a generator, drive, motor, bearing or softstarter, ABB’s experts are on hand to offer technical advice from dimensioning through to potential energy saving.

When you’ve decided on the right product, ABB and its global network of Value Providers can help with installation and commissioning. They are also on hand to support you throughout the operation and maintenance phases of the products life cycle, providing preventive maintenance programs tailored to your facility’s needs.

ABB will ensure you are aware of any upgrades or retrofit opportunities. If you’ve registered your drives and motors with ABB, then its engineers will proactively contact you advising on your most effective replacement option. All of which helps maximize performance, uptime and efficiency throughout the lifetime of your powertrain.

With you, wherever you are in the world

Partnering with ABB gives you access to some of the world’s most innovative technology and thinking.

Global reach

ABB operates in over 100 countries with its own manufacturing, logistics and sales operations together with a wide network of local channel partners that can quickly respond to your needs. Stock availability is good, with short delivery times for many products backed by 24-hour spare parts delivery.

In addition, ABB interacts closely with data center industry players including consultants, system integrators, owners and facility managers to help increase data center uptime to an absolute maximum, eliminate risks and improve PUE.

ABB has seven global R&D centers with more than 8,000 technologists and invests $1.5 billion annually on innovation.

End-to-end product portfolio

Alongside its diverse portfolio of VSDs, motors and generators, ABB offers data centers:

- Medium voltage components and systems such as air- and gas-insulated switchgears, uninterruptible power supply units, relays, ultra-fast earthing switches, Is-limiters to reduce high short-circuit currents and more.

- Low voltage components and systems such as switchgears, uninterruptible power supply units, breakers, industrial plugs and sockets, RCD blocks, power distribution units, remote power panels, a wide range of scalable PLCs and HMIs and more.

- Digital solutions including ABB Ability™ crossproduct and system offering providing intelligence all the way to the component level, improving overall visibility and making the system simple, reliable and sustainable.

Streamline sourcing

ABB’s end-to-end product and services portfolio streamlines your sourcing and purchasing activities and standardizes processes across multiple sites, saving you money on spare part inventories while reducing maintenance costs.