Benefits of Inverter Control on Archimedes Screws

Introduction

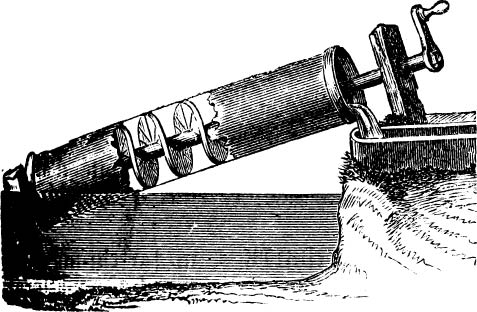

Invented thousands of years ago by the Greek mathematician Archimedes on the occasion of his visit to Egypt. It was used to lift a pool of water to higher levels, usually to transfer water into irrigation channels. It consists of a screw (a helical surface surrounding a central cylindrical shaft) inside a hollow pipe.

The Roman screw was also used to dewater mines in Spain.

The screw is usually turned by windmill, manual labour, cattle, or by modern means, such as a motor. As the shaft turns the bottom end scoops up a volume of water. This water is then pushed up the tube by the rotating helicoid until it pours out from the top of the tube.

Still used today, Archimedes screws are used in sewage treatment plants because they cope well with varying rates of flow and with suspended solids.

Advantages of The Archimedean Screw Pumps

- Simple design – slow speed, simple and rugged design

- Long lifetime (> 20-40 years) and lifetime reliability – The main advantage of a screw pump is its reliability. The simple design, open structure and slow rotation speed makes it a heavy-duty pump with minimal wear that operates for years without trouble.

- Capacity to pump raw water with heavy solids and floating debris. Because of the open structure and large passage between the flights a screw pump can pump raw sewage without the need for a coarse screen before the pump. Floating debris and heavy solids are simply lifted up.

- High efficiency.

- Can run without water. A screw pump can operate even when there is no water in the inlet. Therefore, level control (to prevent ‘dry-running’’) is not needed. The lower bearing does not need cooling.

- No collection sump required = minimum head. A screw pump ‘scoops’ the water directly from the surface and does not need a collection sump. This keeps the pump head to a minimum.

- Easy maintenance (no ‘high skilled’ staff required). A screw pump requires very little maintenance compared to (submersed) centrifugal pumps. This type of pump is very suitable for remote locations.

- ‘Gentle handling’ of biological sludge. Because of the low rotational speed and large opening between the flights, screw pumps do not damage the activated sludge (whereas the high speed rotating centrifugal pumps will completely shred the biological flock).

- Pump capacity is self-regulating with incoming level. When incoming water-level goes down, at dry weather flow, the screw pump ‘automatically’ pumps less water.

- Can be used for capacities from 15 litres/sec up to max 11 m3/sec.

- Come in 3 basic forms: built in the traditional concrete trough, with steel trough liner and the prefabricated, ‘ready to install’ compact units.

Benefits of Inverter Control on Archimedes screws

Applications

The excellent qualities of Archimedean Screw Pumps make them ideally suitable for:

- Sewage Treatment Plants: Sewage Inlet Pumps – The use of Archimedean screw pumps makes it possible to lift large quantities of sewage to a higher level without the need of installing a screen upstream below ground level.

- Storm Water Pumping Stations (Flood Control) – Storm Water Pumping Stations are often waiting in stand-by mode (for 80% of the year) but when heavy rainfall suddenly strikes, they must be immediately ready to start pumping thousands of cubic meters of polluted rainwater containing lots of debris.

- Drainage Pumping Stations – the typical problem of drainage pumping stations is the fluctuation in inlet level. The screw pumps are ideally suitable to handle this fluctuation in inlet level because the pump efficiency.

- Industrial Waste Water: Cooling Water Outfall Pumps, Refineries: for oily sludge and waste water; Potato processing industry, Sugar industry, etc.

Benefits of Inverter Control on Archimedes screws

This is not a common inverter application but there are benefits in using inverter speed control on Archimedes Screws:

- Gentle starting – reduced starting currents and motor heating.

- Gently starting – reduced mechanical stresses, longer V belt and gearbox life.

- Reduced number of starts – using variable speed means matching flow to speed, not on – off.

- Reduced number of stops – at every stop the screw will empty itself needing to be re-primed on the next start – this saves energy.

- IDS’ unique Archimedes control method saves around 15% energy when compared to on – off control.

- Reduced power consumption during dry weather flow if one screw needs to left running (e.g. to mix with RAS).

- Speed control allows control of flow exactly to the consent flow.

- Unity power factor – reduces the current drawn.

To find out more about inverter control of screws contact IDS engineers on 0115 944 1036 or by email [email protected]. IDS are ABB’s leading inverter AVP centrally located in Ilkeston, Derbyshire.