Are Inverters Phase Sensitive?

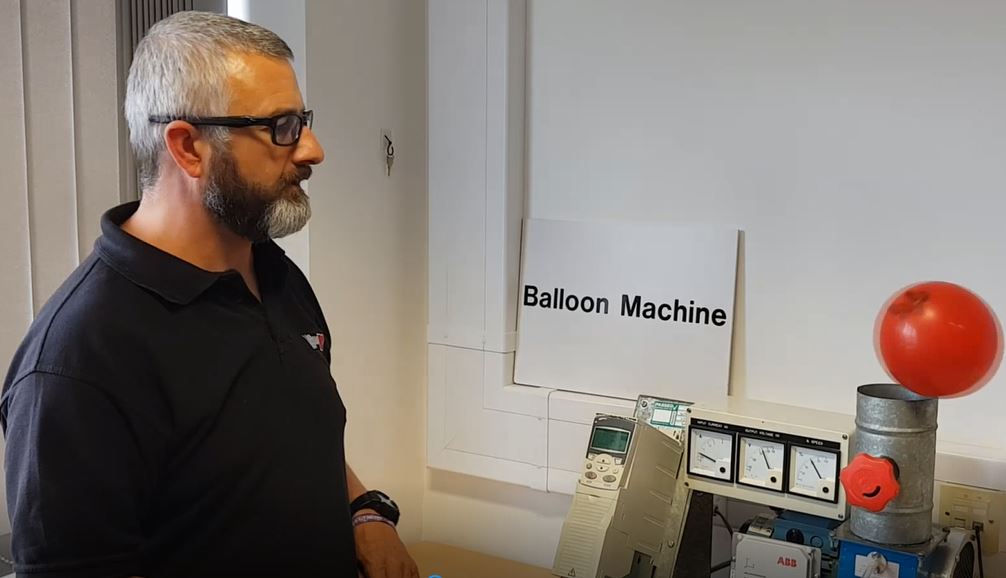

In this article, Blaise Ford, MD of Inverter Drive Systems, answers a question we are frequently asked: Are Inverters Phase Sensitive? Blaise explains: “Inverters take single or three phase mains, rectify it and then chop it up again to give variable frequency, variable voltage output. The three phase rotation, brown-black-grey or brown-grey-black, is lost when […]