An Archimedean Screw Saves 8.2% Energy

Severn Trent Water are saving 14 tonnes of CO2 per annum by applying an inverter to an Archimedean Screw.

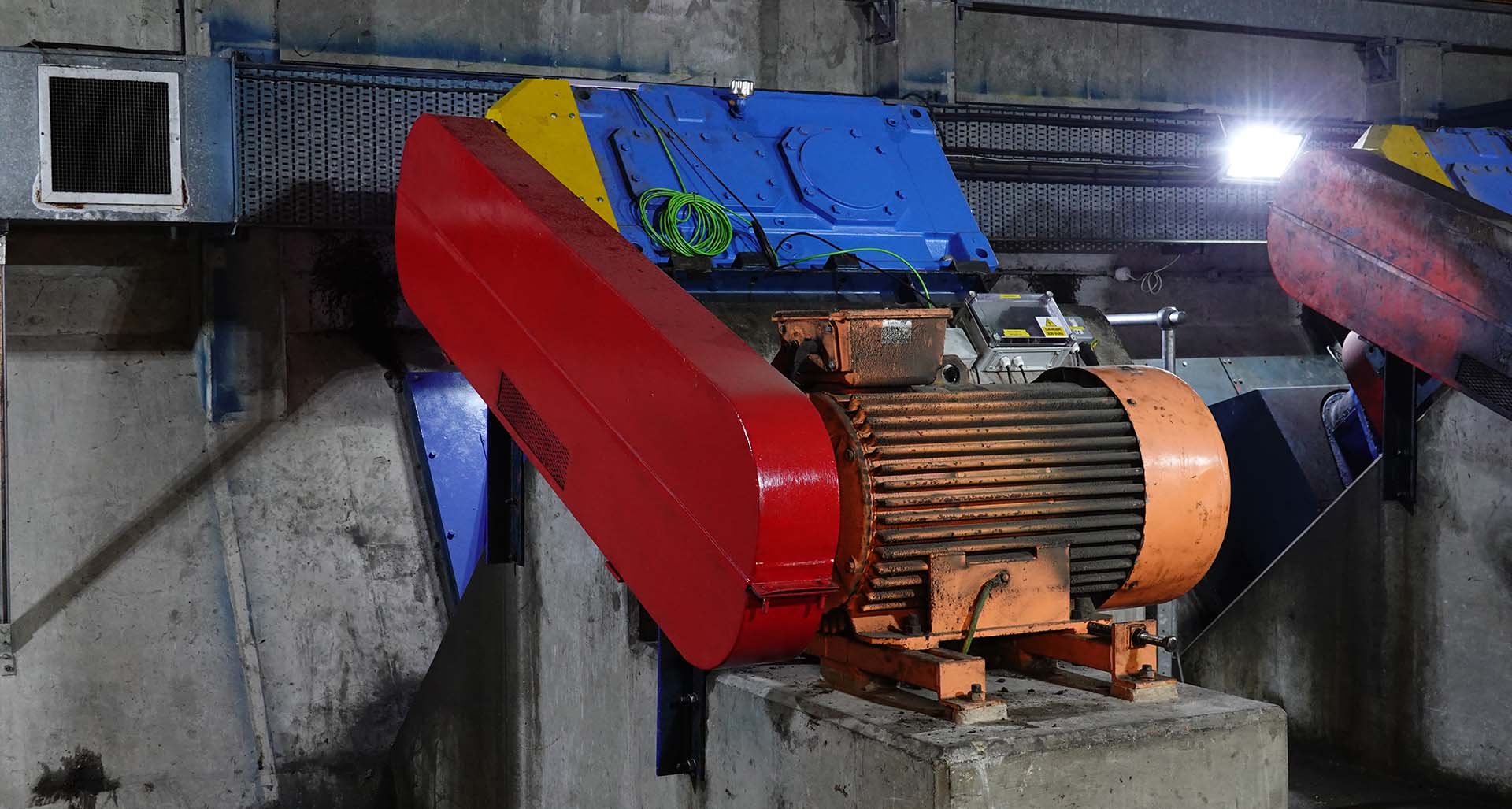

Blaise Ford from IDS worked with Bill Edwards and Lee Tuckwell from Severn Trent Water, to apply inverter technology to an Archimedean Screw. At the Severn Trent Water Netheridge site there are three Archimedes screws, Duty/Assist/Stand-by, 110kW, star delta starting with two 20 year old motors and a recently installed IE3 motor on screw Pump No1. The duty pump runs 24/7 to meet process requirements.

The inverter will save 8.2% of the energy this application previously used. That equates to 14 tonnes of CO2 per annum! Also, when using an inverter there are softer mechanical starts which reduces V Belt and Gearbox stresses.

An Archimedean Screw Saves 8.2% Energy – The Solution

A permanent ACQ580 inverter was fitted to screw No 1. IDS’s screw control was applied, keeping the lead screw role. This control method uses the inlet well level signal to control the speed of the screw and operates in three modes:

a) Low flow – the screw runs at minimum speed (35.4Hz in this case) reducing the revolutions of the screw, increasing its operational

life and saving a small amount of energy.

b) Medium flow – the inverter controls the inlet well level saving more energy.

c) High flow – the inverter runs at full speed to give maximum flow.

An Archimedean Screw Saves 8.2% Energy – The Results

The ACQ580 inverter totals kWh and hours run in its registers. In fixed, full speed mode, the average power was 85.6kW. In IDS control mode, average power was 78.6kW.

This is an energy saving of 7.0kW or 8.2%. This is an annual monetary saving on the duty pump of over £12,000. The payback on the investment is < 15 months. This inverter solution will save 14 tonnes of CO2 per annum.

Additional Inverter Benefits

In addition to saving energy there are additional significant benefits to inverter control on Archimedean Screws:

a) Smooth starts. Originally, the starting method was star-delta. Whilst this does give a form of gentle starting, there is a large current and torque pulse when delta is applied. This meant the V belts and gearbox were stressed mechanically reducing their operational lives.

b) Reduced speed. By using the inlet sump level to control the screw’s speed, the overall number of revolutions of the screw is reduced by an estimated 20%. Whilst it is difficult to relate this directly to the screw’s life, it must lengthen the time between major overhauls. This then reduces whole life equipment costs.

Working with IDS

At IDS we are highly experienced at supporting the Water industry with inverter technology. Applying solutions to various applications including Archimedes Screws. To understand how we can assist your clean or wastewater site please contact us on 0115 944 1036 or email [email protected]