Selecting Motors And Drives For Explosive Atmospheres

When selecting variable speed drives and motors for potentially explosive atmospheres, the manufacturer’s instructions and recommendations must be followed, otherwise explosion protection measures will be compromised. ABB’s Luciano Santos and Andrew Bould share some advice.

Throughout the food and beverage sector, variable speed drives (VSDs) and electric motors are renowned for contributing to productivity improvement and energy efficiency. However, their use needs to be very carefully considered in applications within potentially explosive atmospheres – also known as “hazardous areas” or “hazardous locations”.

Flour dust, for instance, is potentially explosive and in high enough concentrations, when combined with oxygen and an ignition source, such as a hot surface or a spark, it can combust. In enclosed areas it can have devastating results. In fact, airborne flour dust is even more explosive than coal dust. Since it is not realistic to eliminate flour dust and oxygen from a typical bakery facility, ATEX regulations instead focus on removing ignition sources.

It is for these reasons that correctly dimensioning a motor and VSD combination is critical, as getting this wrong can compromise explosion protection measures.

The key is to follow the motor manufacturer’s instructions and recommendations. For instance, the instructions are intended to prevent the motor from overheating or creating any sparks. Meanwhile, the accompanying VSD must never be installed within a potentially explosive atmosphere and needs to be located away from the motor, in a safe area.

Choosing a motor and drive

Selecting a motor and drive combination starts by gathering the customer’s requirements including ambient conditions, supply voltage and frequency, motor shaft speed area, motor output load, load type and overload requirement, efficiency requirements, as well as the zone, gas/dust group, temperature class and Ex protection type. Armed with this information, the correct motor type can be selected.

Motor protection types

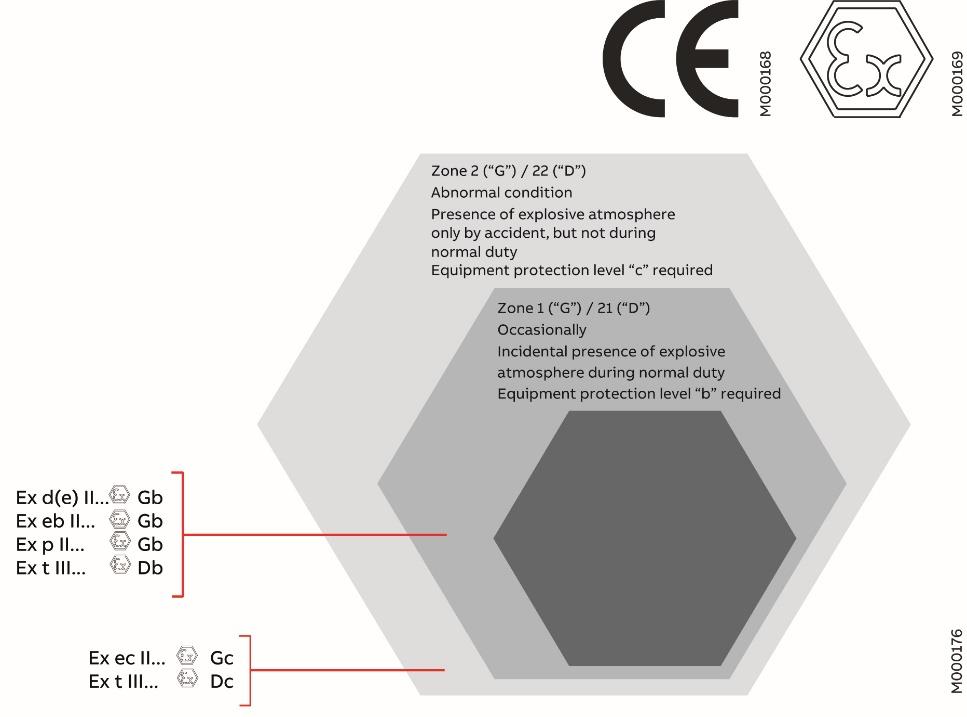

Motors are directly connected to the load or machine within the potentially explosive atmosphere. These atmospheres have a defined zone classification which defines the minimum safety level (category) to which the motors must comply. The category defines the permitted motor protection types.

Motors can be classified by equipment protection level (EPL) according to the IEC/EN standards. The EPL indicates the motor’s inherent risk of ignition. The purpose of this classification is to make it easier to select motors for different zones. For motors, the EPL marking is included in the Ex marking, and the equipment category is included in the CE marking.

Classification into categories is particularly important, because all the end user’s inspection, maintenance and repair duties will depend on the category of the product/ equipment, not on the zone where it is installed. The following highlights examples of Ex motor protection types and methods given in the IEC/EN standard to ensure safe operation when a motor is fed from a VSD.

Flameproof – Protection type Ex d

When using protection type Ex d with an AC drive, the motor must be tested together with the drive for the duty intended and with the protective device provided. Alternatively, use direct temperature protection with embedded temperature sensors and with sufficient margin to protect the bearings or the rotor. The actions of the protective devices used must cause the motor to be disconnected. Only external surface temperature needs to be considered for the Ex temperature class.

Increased safety “ec” (formerly “Non-sparking Ex nA”) – Protection type Ex ec

With protection type Ex ec it is important that the motor is tested with the drive or a comparable drive. Alternatively, the motor’s temperature class is determined by calculation or by using direct temperature control with embedded temperature sensors. The action of the protective device must cause the motor to be disconnected. Surface temperature of any part (inside or outside) must not exceed the Ex temperature class limit.

Dust-ignition-proof – Protection type Ex t

Using this protection type with an AC drive requires that both the motor and drive are tested together for this duty and with the protective device provided. Alternatively, use direct temperature protection with embedded temperature sensors and with sufficient margin to protect the bearings or rotor. The action of the protective device must cause the motor to be disconnected. Only external surface temperature needs to be considered for the Ex temperature class.

Ingress protection to IP55 or IP65 prevents any dust from entering the motor, and therefore from reaching any internal hot surfaces. Windings can be equipped with temperature sensors to protect the insulation, while thermistors are fitted to limit the surface temperature of the motor.

Increased safety “eb” – Protection type Ex eb

For this protection type, when used with an AC drive, the standard requires that the motor is tested in association with the specific drive and protective device for this duty. A combined heat run test is mandatory. Surface temperature of any part (inside or outside) must not exceed the Ex temperature class limit.

Dimensioning the motor and drive

When sizing a motor for variable-speed use, continuous thermal dimensioning and short-time overload capacity must be considered. Also, limiting the switching frequency via Ex parameters will de-rate the amount of current and should be considered in the calculations.

Drive dimensioning can be performed using motor load capacity curves. These curves show the maximum permitted continuous output torque of the motor as a function of supply frequency. The output torque is given as a percentage of the motor’s nominal torque. The load capacity curves are based on nominal supply voltage. The maximum speed of the motor must not be exceeded.

Load capacity curves are calculated for a specific switching frequency depending on the drive type. Since the switching frequency is different for different drives and load types, to ensure safe operation the combination of motor and drive must be tested for the specific type of protection needed. The alternative is to connect the internal temperature sensors in the motor to a certified PTC/Pt100 relay that controls the main contactor of the drive and disconnects the motor from the power supply if the temperature limit is exceeded. Any filters that are fitted must be considered when dimensioning the motor.

Other factors to consider include short-time overload capacity, ambient conditions and voltage drops in long cables.

Insulation and filters

Choose the insulation and filters according to voltage and frame size. Different motor manufacturers have different instructions.

Thermal protection

Depending on the motor protection type, manufacturers take a different approach to fulfilling the requirement of the standards. Check whether the combination has been type-tested and whether overtemperature protection is required in the certificate. Choose the ATEX-certified safety devices accordingly.

Installation

Follow the installation instructions from the motor manufacturer – especially the cable and EMC recommendations in accordance with local regulations. Configure the drive according to the values on the motor rating plate and drive rating plate. Check that the drive’s switching frequency can be limited to the value required by the motor manufacturer. Additional safety can be achieved by commissioning the load capacity curve, if available.

ABB (ABBN: SIX Swiss Ex) is a technology leader that is driving the digital transformation of industries. With a history of innovation spanning more than 130 years, ABB has four customer-focused, globally leading businesses: Electrification, Industrial Automation, Motion, and Robotics & Discrete Automation, supported by the ABB Ability™ digital platform. ABB’s Power Grids business will be divested to Hitachi in 2020. ABB operates in more than 100 countries with about 147,000 employees.