PID Control Using an Inverter

In this video, Inverter Drive Systems Ltd Account Manager, Simona York, demonstrates PID Control using an Inverter.

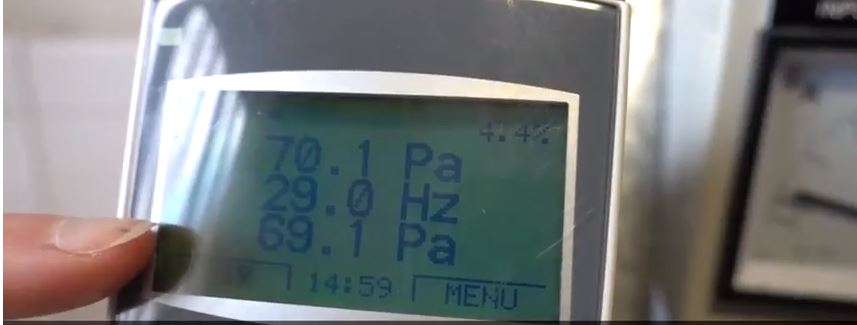

In the demonstration, Simona uses a demonstration rig, our Balloon Machine, which consists of an ABB inverter, a motor, a fan with damper (which can be used to control the flow) and a pressure sensor. On the keypad of the inverter, the first reading is the set point, 70 Pascals in this case. The second reading is the speed of the frequency and the third is the actual pressure reading. We also have gauges that show the current, the voltage and the speed of the motor as a percentage.

PID Control Using an Inverter

Usually, in a process we are trying to keep a variable constant, for example; level, flow, temperature or as in our case, the pressure.

In the video you see an example of a steady state in a low demand or low flow. We can see the damper is slightly open. The inverter reading shows 70 Pascals as the actual reading, 70 Pascals is the set point and the motor speed is currently 50%. Watch what happens when we increase the demand or the flow, by opening the damper more. You can see from the inverter keypad readings, by opening the damper, the pressure dropped from 70 Pascals to around 65. To compensate, the inverter automatically increases the speed of the motor from 50% to 60% in order to restore the pressure to the set point of 70 Pascals.

PID Control Using an Inverter

In conclusion, PID Control using an inverter is the best way of controlling a process, whilst achieving the maximum energy saving.

To find out more about PID Control using an inverter or to discover the many other features of the ABB range of inverters, call IDS on 0115 944 1036 or email [email protected]